Essential Considerations for Pipe Jacking Equipment Selection

Selecting the optimal pipe jacking machine for your construction project is a critical decision that impacts project success, timeline, and cost-effectiveness. The right equipment choice ensures smooth operations, minimal ground disturbance, and efficient installation of underground utilities. With various pipe jacking machine options available in the market, understanding the key factors that influence selection becomes paramount for construction professionals and project managers.

Modern pipe jacking technology has evolved significantly, offering sophisticated solutions for underground pipeline installation. These advancements have made it possible to execute complex projects in challenging ground conditions while maintaining surface stability. However, this variety also means that careful evaluation is necessary to match equipment capabilities with specific project demands.

Technical Specifications and Performance Parameters

Machine Diameter and Thrust Force

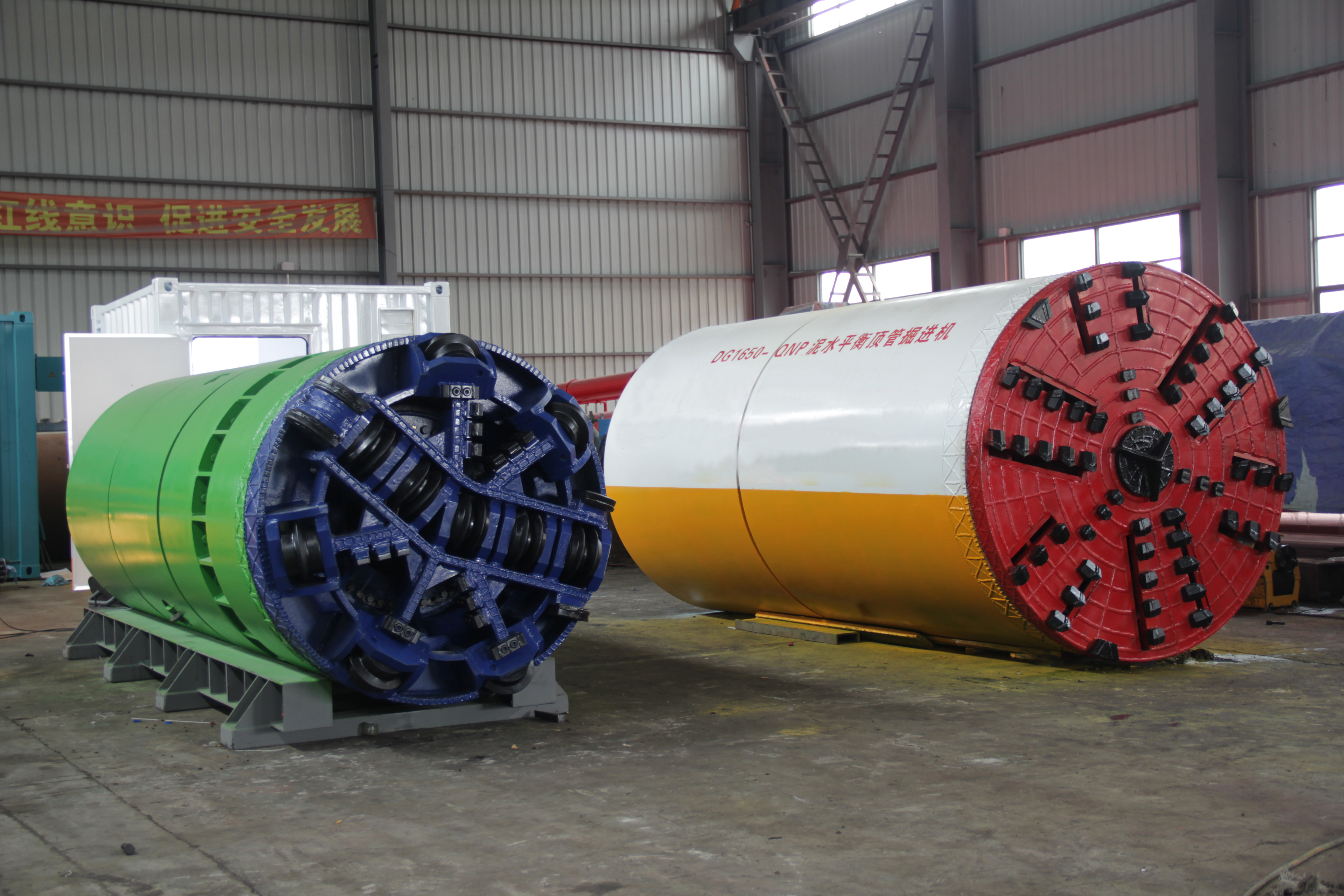

The diameter of the pipe jacking machine must align precisely with the intended pipeline specifications. Typical diameters range from 600mm to 3000mm, though specialized equipment can accommodate larger sizes. The machine's thrust force capability is equally crucial, as it determines the maximum jacking distance and the ability to overcome friction forces during operation.

Thrust force requirements vary depending on pipe diameter, jacking distance, and soil conditions. A general rule of thumb suggests calculating the required thrust force based on pipe external diameter and anticipated friction coefficient. Modern pipe jacking machines typically offer thrust capacities ranging from 500 to 3000 tonnes, ensuring sufficient power for most applications.

Control Systems and Guidance Technology

Advanced control systems are essential for maintaining accurate line and grade during jacking operations. State-of-the-art pipe jacking machines incorporate laser guidance systems, gyroscopic navigation, and real-time monitoring capabilities. These features enable operators to make precise adjustments and maintain desired trajectories throughout the installation process.

The control system should offer user-friendly interfaces, data logging capabilities, and remote monitoring options. This technology helps prevent deviation errors and reduces the risk of costly corrections during construction.

Ground Condition Compatibility

Soil Type Assessment

Different ground conditions require specific cutting head configurations and machine features. Soft soils may need closed-face machines with slurry systems, while rocky conditions demand robust cutting tools and higher torque capabilities. A thorough geotechnical investigation helps determine the most suitable pipe jacking machine configuration.

Modern pipe jacking machines often come with interchangeable cutting heads, allowing adaptation to varying ground conditions along the pipeline route. This flexibility is particularly valuable in projects where soil conditions change significantly between launching and receiving shafts.

Groundwater Management

The presence of groundwater significantly influences machine selection. Earth pressure balance (EPB) or slurry shield pipe jacking machines are essential in water-bearing soils to prevent ground collapse and maintain face stability. These systems effectively manage groundwater pressure while ensuring continuous operation.

Advanced sealing systems and water management features protect sensitive components and maintain operational efficiency even in challenging hydrogeological conditions. The machine's ability to handle water inflow while maintaining face pressure is crucial for project success in high water table environments.

Operational Requirements and Site Constraints

Site Access and Setup Considerations

The physical constraints of the construction site play a vital role in machine selection. Available space for launching shafts, surface equipment, and support systems must be carefully evaluated. Compact pipe jacking machines might be necessary in urban environments with limited working space.

Additionally, consideration must be given to machine assembly and disassembly requirements, transportation logistics, and crane capacity needs. The selected equipment should align with site-specific limitations while maintaining operational efficiency.

Project Timeline and Production Rates

The pipe jacking machine's advancement rate capability must align with project schedule requirements. Modern machines can achieve impressive production rates, but actual performance depends on various factors including ground conditions, pipe segment length, and system efficiency.

Equipment reliability and maintenance requirements also influence production rates. Selection should consider the manufacturer's track record, availability of spare parts, and local technical support to minimize downtime and maintain steady progress.

Economic Considerations and Long-term Value

Initial Investment and Operating Costs

While initial equipment cost is important, the total cost of ownership should guide selection decisions. This includes considerations for energy consumption, maintenance requirements, and operator training needs. Modern pipe jacking machines often incorporate energy-efficient systems that reduce operating costs over the project lifecycle.

The potential for equipment utilization in future projects should also factor into the investment decision. Versatile machines that can handle various pipe sizes and ground conditions offer better long-term value despite higher initial costs.

Performance Optimization Features

Advanced pipe jacking machines include features that optimize performance and reduce operational costs. Automated lubrication systems, real-time performance monitoring, and predictive maintenance capabilities help maximize efficiency and minimize unexpected downtime.

These technological advantages often justify higher upfront costs through improved productivity, reduced labor requirements, and enhanced project outcomes. The ability to monitor and adjust operations in real-time contributes to both efficiency and quality control.

Frequently Asked Questions

What is the typical lifespan of a pipe jacking machine?

The lifespan of a well-maintained pipe jacking machine typically ranges from 10 to 15 years, depending on usage intensity and operating conditions. Regular maintenance and proper operation can extend this lifespan significantly, making it a valuable long-term investment for construction companies.

How do weather conditions affect pipe jacking operations?

While pipe jacking operations occur underground, extreme weather conditions can impact surface operations and equipment performance. Modern pipe jacking machines are designed to operate in various climates, but proper planning for weather protection and temperature control may be necessary for optimal performance.

What safety features should be considered when selecting a pipe jacking machine?

Essential safety features include emergency shutdown systems, pressure monitoring devices, gas detection systems, and robust communication equipment. The machine should comply with current safety standards and regulations, offering comprehensive operator protection and environmental safeguards.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY