Geological Conditions: Soil Stability, Rock Hardness, and Groundwater Impact

Evaluating Geological and Geotechnical Analysis of Terrain for Tunnel Drilling Machine Selection

According to a recent geological study from 2023, construction teams that did thorough soil testing saw tunneling delays drop by around 62%. When picking tunnel boring machines, engineers need to look at how fractured the bedrock is, check those soil plasticity numbers, and review past groundwater activity patterns. Getting this right helps match the equipment to what's actually underground. Using all this information makes sure the machines work properly without running into unexpected problems down below. Plus it gives better control over how long things will take overall for the whole project.

Impact of Soil and Rock Composition on Tunnel Drilling Machine Performance

The hardness of rock formations and how abrasive the soil is has a major impact on how well tunnel boring machines work and how much they wear down over time. When dealing with really tough granite that has a compressive strength above 150 MPa, these machines need cutterheads capable of applying around 380 kN per square centimeter of thrust force. That's actually about 45 percent more than what's needed when working through softer clay soils. Another problem comes from areas rich in cobbles within alluvial deposits. These conditions cause disc cutters to wear out roughly 32 percent faster compared to working in uniform shale beds. This kind of wear means maintenance crews have to stop operations more often and spend extra money fixing equipment damage. For projects facing these kinds of challenges, it makes sense to invest in machines equipped with tougher cutting tools and systems that can adjust their thrust pressure as conditions change during excavation.

Assessing Groundwater Presence and Pressure in Soft Ground Tunneling

Porous soils present unique challenges when water flows through them at over 30 liters per second. At these levels, engineers typically need to deploy pressurized-face tunnel boring machines (TBMs) just to keep the excavation face from collapsing entirely. The situation gets even trickier when hydraulic pressures climb above 2.5 bar. That's when bentonite injection systems become absolutely essential for keeping things stable during digging operations. This matters a lot particularly in city settings where unexpected water leakage could damage buildings, roads, or underground utilities located close by. Managing groundwater effectively isn't just about worker safety either. It directly impacts how fast construction teams can progress through wet soil layers without constantly dealing with equipment downtime or structural failures.

Challenges of Mixed Ground Conditions for Tunnel Boring Machine Operation

When tunnel boring machines move from soft soil into hard rock, their progress slows down quite a bit. Industry data shows these transitions can cut average advance rates by around 27%. The good news is modular TBMs with those special hybrid cutterheads actually work better in mixed ground conditions. These machines combine rippers for breaking up tough material with disc cutters for smoother sections, which boosts efficiency by about 18% when dealing with layers of sandstone and clay. Engineers really appreciate these flexible designs because they help manage the constant surprises that come with digging through complicated rock formations where nothing stays predictable for long.

Tunnel Boring Machine (TBM) Types: EPB, Slurry, Shield, and Multimodal Options

Understanding TBM Types and Selection Criteria Based on Project Needs

When choosing the right Tunnel Boring Machine, engineers typically consider three main things: what kind of ground they're dealing with, how big the project is, and any environmental restrictions that might apply. EPB machines have become the go-to option for digging tunnels in soft ground areas within cities, accounting for around 62% of all subway construction worldwide according to recent reports from underground construction firms. For places where the soil is really wet and saturated, slurry TBMs work better, whereas the hard rock versions excel when working through solid, stable rock formations. Multimodal TBMs do come at a price premium of about 15 to 20% upfront compared to standard models, but this extra investment pays off over time because these versatile machines can adjust their torque and thrust settings on the fly when encountering different types of material during excavation, which helps minimize risks associated with unpredictable ground conditions.

EPB vs. Slurry vs. Hard Rock TBMs: Matching Tunnel Drilling Machines to Ground Conditions

Earth Pressure Balance Tunnel Boring Machines keep the excavation face stable by matching the pressure from the soil being dug with what's inside the machine chamber. This makes them work really well in sticky soils such as clay and silt. For underwater tunnel projects, slurry systems come into play. These systems pump pressurized bentonite mud against the face to create a watertight seal. Groundwater leaks are a big problem down there, and fixing those issues can cost over 740 thousand dollars according to Ponemon research from last year. When dealing with hard rock formations like granite or basalt, different machines are needed. Hard rock TBMs have special tungsten carbide disc cutters that can handle massive rock pressures reaching around 250 megapascals. These tough little tools let operators push through even the most stubborn rock layers without losing efficiency.

| TBM Type | Key Components | Optimal Ground Conditions | Operational Limitation |

|---|---|---|---|

| EPB | Screw conveyor, plenum | Soft soils (clay, silt) | High groundwater requires additives |

| Slurry | Hydrocyclones, slurry mix | Water-saturated soils | Complex slurry treatment systems |

| Hard Rock | Disc cutters, grippers | Igneous/metamorphic rock | Limited flexibility in soft zones |

Multimodal and Variable Density TBMs for Complex or Heterogeneous Geologies

When dealing with construction sites where soil and rock layers keep changing back and forth something that happens in around 38 percent of all cross country railway projects multimodal tunnel boring machines really shine. The beauty of these machines is their ability to switch from earth pressure balance mode to slurry mode whenever the ground composition shifts beneath them. Some advanced models come equipped with variable density systems too. These systems work smartly by tweaking the speed of the cutting head and adjusting the thickness of the slurry mixture on the fly. Field tests show this kind of real time adaptation cuts down unexpected stoppages by about twenty percent when working through those tricky mixed face conditions. A recent study published in the Geotechnical Engineering Journal backs up these findings from last year.

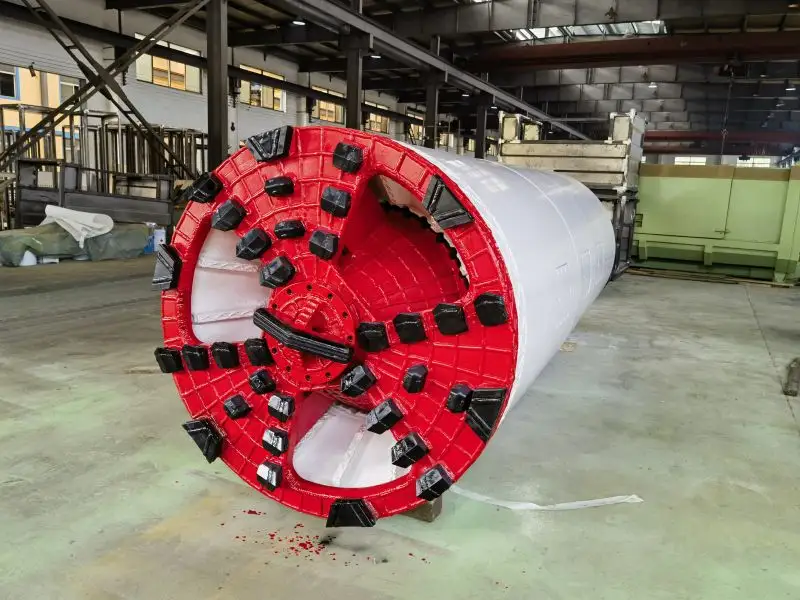

Cutterhead Design and Tool Configuration Across Different Tunnel Drilling Machine Types

The way cutterheads are designed really affects how well they work and how long they last. For EPB machines, helical scrapers do the job of moving soil efficiently. Hard rock TBMs take a different approach though, using between 17 and 25 disc cutters laid out in concentric rings so they can break up rock effectively. Some newer designs combine features with hybrid cutterheads that let operators swap out tools as needed. According to Tunneling Association data from 2023, these hybrid systems actually last about 30% longer when working through abrasive sandstone. That kind of improvement means better uptime for tunnel projects and helps keep maintenance costs down over time.

Project Scale and Performance Requirements: Length, Diameter, and Advance Rate

How Tunnel Length Influences Tunnel Drilling Machine Deployment and Efficiency

When digging longer tunnels, tunnel boring machines need to be built tougher and work non-stop for extended periods. For projects over 5 kilometers long, engineers usually specify cutterheads that are around 25 to maybe even 30 percent stronger, along with automated systems for installing tunnel segments so operations don't grind to a halt. According to recent research from last year's geotech conference, thrust cylinders tend to wear out about 18% quicker when machines run past the 3 km mark. This finding really underscores why good maintenance scheduling matters so much these days, as nobody wants their project stuck waiting for repairs during critical phases.

Matching Advance Rate Requirements with Machine Capability and Accuracy

How fast a tunnel advances is really connected to how long the whole project will take. Most urban subway projects aim for around 15 to 20 meters each day. But things change when we dig deeper for scientific research or geological studies where accuracy matters more than speed, so those projects might only move forward 5 to 8 meters a day instead. The sweet spot for efficiency happens when the machine's torque output, which typically ranges from 4,000 to 12,000 kilonewton meters, aligns properly with the strength of the rock being drilled through. Machines that are too powerful for softer ground actually end up wasting between 14 and 18 percent extra energy, based on recent industry data from 2024. This shows just how important it is to get the mechanical specs right for different types of soil conditions.

Selecting Machine Diameter Based on Tunnel Geometry, Alignment, and Depth

Diameter selection integrates structural, functional, and geomechanical considerations:

- Utility tunnels: 3–5 meter bores optimize space in dense urban areas

- Rail tunnels: 8–12 meter diameters accommodate track layouts and clearance requirements

- Hydroelectric conduits: 14–18 meter tunnels manage high-volume water flow

Depth further influences design—each 100-meter increase in overburden raises rock pressure by 2.7 MPa, requiring segmental linings to be 15–20% thicker to maintain structural integrity.

Urban vs. Deep-Bore Projects: Balancing Size, Access, and Operational Constraints

City tunnel boring machines deal with around 40 percent more space constraints because of all the buried pipes, cables, and buildings already there, which usually means they have to be launched in pieces rather than whole. Mountain tunnels going deeper than 500 meters face completely different challenges though. These underground behemoths contend with water pressure reaching as high as 10 bars, so engineers typically equip them with special pressurized face systems to keep things stable. Looking at data from 87 real world projects reveals something interesting: construction teams working in tight urban areas only get about 22% fewer meters done each day compared to those operating in open spaces. This kind of information really highlights why it's so important to model how machines will perform based on specific job site conditions when picking equipment for tunneling jobs.

Thrust, Torque, and Mechanical Capacity in Tunnel Drilling Machine Performance

Measuring Thrust Force and Torque Under Variable Geological Resistance

The amount of thrust and torque a Tunnel Boring Machine needs tells engineers a lot about how well it can cut through different types of rock and soil. Recent research published in Nature back in 2025 showed just how much these requirements can change depending on what material the machine is working with. Soft sediments need way less force compared to tough sandstone, sometimes making a difference of three times the required thrust. To handle all this variation, engineers rely on something called Ground Penetration Index calculations. These help them tweak the torque settings so the cutting head doesn't get stuck. Take cohesive clay for example – most machines need around 12 to 18 kilonewtons per square meter to push through. But switch to granite and suddenly we're looking at 35 to 50 kN/m² instead. That kind of jump makes it clear why modern TBMs need smart systems that can adjust power output on the fly as conditions change underground.

Balancing Mechanical Power With Ground Conditions for Optimal Efficiency

Getting efficient tunneling right means aligning torque curves and thrust profiles with what the local geology can handle. Push too hard in soft ground and we waste around 20-25% extra energy according to some industry reports from last year. On the flip side, machines that aren't powerful enough when digging through hard rock tend to wear out components about 40% faster than normal. The GEplus study from 2025 backs this up, though there are always questions about how field conditions compare to lab results. Today's tunnel boring machines come equipped with smart control systems that keep an eye on cutterhead vibrations and rock density as they go. These systems adjust RPM settings, apply just the right amount of thrust, and manage slurry flow automatically. As a result, operators can maintain between 93% to nearly 97% efficiency even when moving through mixed ground conditions that change constantly underground.

Cost Considerations: Initial Investment, O&M, and Total Cost of Ownership (TCO)

Initial Investment Analysis for Tunnel Boring Machine Procurement

The price tag for tunnel boring machines varies quite a bit depending on what kind of machine is needed. Compact EPB models typically start around $2 million, while those big slurry machines for larger tunnels can easily go beyond $20 million. What really drives up the cost? Customizing the cutterhead accounts for about 15 to 25 percent of the base price alone. Ground stabilization systems also eat into the budget, and then there's the issue of scale. When a project requires doubling the bore diameter from 6 meters to 12 meters, expect costs to jump anywhere between 180 and 220 percent. For anyone making these big purchases upfront, it's important to think not just about what's needed right now but also how unpredictable underground conditions might throw a wrench in even the best laid plans down the road.

Operation and Maintenance (O&M) Costs Across Tunnel Drilling Machine Types

O&M expenses vary significantly by machine type and geology. Hard rock TBMs incur 35–45% higher tool replacement costs—averaging $580/hour in granite—compared to EPB machines in soft soils. Primary cost factors include:

- Energy use: 480–900 kWh per hour, depending on resistance

- Labor: 12–18 technicians for round-the-clock shifts

- Wear parts: Disc cutters last 80–120 hours in quartzite versus over 300 hours in clay

These variables emphasize the importance of condition-based maintenance strategies.

Calculating Total Cost of Ownership for Long-Term Tunneling Projects

The Total Cost of Ownership, or TCO as it's often called, includes things like equipment depreciation over roughly 10 to 15 years, plus all those costly hours lost when machines break down. Think about it: in big city environments alone, downtime can cost anywhere from $12k to $45k every single hour! Then there are these geological risks where unpredictable underground conditions typically drive costs up by around 25% to 40%. Recent studies from 2025 showed something interesting though. When companies invest in newer tunnel boring machines equipped with smart maintenance systems, they actually save money overall even though the upfront investment is about 22% more expensive. And let's not forget urban areas present their own challenges. Projects in cities tend to run about 30% pricier per kilometer because of all the noise restrictions, moving existing utilities, and dealing with limited space for operations. That's why getting realistic about costs from day one matters so much for any project planning.

FAQ

What are the main considerations when selecting a Tunnel Boring Machine?

The main considerations when selecting a Tunnel Boring Machine (TBM) include the type of ground conditions, project scale, environmental restrictions, and the specific engineering requirements like diameter and advance rate.

How do mixed ground conditions affect TBM operation?

Mixed ground conditions can significantly slow down TBM operations by around 27% when moving from soft soil to hard rock. However, modular TBMs with hybrid cutterheads can improve efficiency by about 18% in these conditions.

What are the key cost factors for TBMs?

Key cost factors for TBMs include the initial purchase price, which varies based on machine type and customization, as well as ongoing operation and maintenance costs, such as energy consumption, labor, and wear parts replacement.

What's the difference between EPB, slurry, and hard rock TBMs?

EPB TBMs are used for soft soil conditions and maintain face stability through pressure balance. Slurry TBMs are suitable for water-saturated soils and use bentonite to create seals. Hard rock TBMs have tougher components for digging through solid rock formations.

How does tunnel length influence machine efficiency?

Longer tunnels require more robust TBMs with stronger cutterheads and efficient segment installation systems. Efficiency can drop by 18% if machines are not adequately maintained for projects extending beyond 3 kilometers.

Table of Contents

-

Geological Conditions: Soil Stability, Rock Hardness, and Groundwater Impact

- Evaluating Geological and Geotechnical Analysis of Terrain for Tunnel Drilling Machine Selection

- Impact of Soil and Rock Composition on Tunnel Drilling Machine Performance

- Assessing Groundwater Presence and Pressure in Soft Ground Tunneling

- Challenges of Mixed Ground Conditions for Tunnel Boring Machine Operation

-

Tunnel Boring Machine (TBM) Types: EPB, Slurry, Shield, and Multimodal Options

- Understanding TBM Types and Selection Criteria Based on Project Needs

- EPB vs. Slurry vs. Hard Rock TBMs: Matching Tunnel Drilling Machines to Ground Conditions

- Multimodal and Variable Density TBMs for Complex or Heterogeneous Geologies

- Cutterhead Design and Tool Configuration Across Different Tunnel Drilling Machine Types

-

Project Scale and Performance Requirements: Length, Diameter, and Advance Rate

- How Tunnel Length Influences Tunnel Drilling Machine Deployment and Efficiency

- Matching Advance Rate Requirements with Machine Capability and Accuracy

- Selecting Machine Diameter Based on Tunnel Geometry, Alignment, and Depth

- Urban vs. Deep-Bore Projects: Balancing Size, Access, and Operational Constraints

- Thrust, Torque, and Mechanical Capacity in Tunnel Drilling Machine Performance

- Cost Considerations: Initial Investment, O&M, and Total Cost of Ownership (TCO)

- FAQ

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY