The Importance of Alignment Accuracy in Micro Pipe Jacking

Role of Precision in Trenchless Pipeline Installation

Getting things right during trenchless installation means pipelines stay strong and don't run into other underground utilities. Take modern micro pipe jacking machines for instance they can line up pipes within about 25mm accuracy over distances of 100 meters thanks to those fancy laser guides built in. This cuts down on the need for hands-on tweaking by around three quarters when compared to old school techniques. Some research from last year looked at city sewer work and discovered something interesting if pipes drift more than 40mm off course, it adds roughly $120 extra per meter just for fixing roads and moving other services out of the way. That's why these precision tools matter so much in crowded cities where small mistakes can actually damage nearby buildings and their foundations.

Common Challenges Affecting Alignment During Micro Tunneling

Soil variability, buried obstacles, and equipment vibration contribute to alignment drift. Granular soils require 23% more steering corrections than cohesive clays, while uncharted utility lines often necessitate real-time trajectory changes. Operators must maintain jacking speeds between 20–50 mm/min to ensure responsive steering without inducing excessive deflection forces.

Impact of Ground Conditions on Steering Accuracy

Groundwater pressure reduces cutterhead steering effectiveness by 30–40% in saturated sands compared to dry conditions. In boulder-rich glacial till, steering response times must be as fast as 15 seconds to prevent cascading misalignment. Projects in alluvial plains demonstrate 60% higher alignment stability than those in fault-affected zones due to uniform strata composition.

Typical Alignment Tolerances: ±25 mm Over 100 Meters

Industry standards allow a maximum horizontal deviation of 0.25% of tunnel length–equivalent to ±250 mm/km. However, advanced micro pipe jacking operations now consistently achieve ±25 mm/100m through:

- Triple-redundant inclination sensors (±0.01° accuracy)

- Hydraulic articulation systems with 0.5 mm positioning resolution

- 5 Hz real-time data transmission from cutterhead to control cabin

These capabilities enable direct pipe connections without additional joint adjustments in 92% of installations, reducing project timelines by 18–22 days per kilometer.

Core Guidance Systems for Real-Time Alignment Control

Laser Guidance Systems and Their Integration in Micro Pipe Jacking Machines

Laser alignment systems work by shooting reference beams at target boards attached to the cutting head. These systems can spot even tiny deviations down to around 1 mm. Most top manufacturers now pair them with hydraulic steering jacks that automatically adjust the path whenever there's more than +/-5 mm of drift. Take the recent sewer project in Hamburg during 2023 for instance. The team used laser guided micro pipe jacking techniques there and managed to hit almost perfect alignment - getting 99.8% accuracy over the entire 850 meter stretch through tough clay soil conditions. Pretty impressive results considering what they were working with.

Gyroscopic and Inertial Navigation for Non-Line-of-Sight Tracking

Gyrocompasses measure angular velocity at 200 Hz, maintaining course during curved drives where laser visibility is obstructed. When paired with inertial measurement units (IMUs), they deliver <3 cm positioning accuracy–even through 90° turns–making them essential for complex urban utility networks requiring precise elevation control.

Electronic Theodolites and Target Cameras for Continuous Monitoring

Motorized theodolites track prism targets on the jacking machine with 0.5-arcsecond resolution, cross-verified with CCTV pipeline footage. This dual verification method reduced alignment disputes by 40% in a recent transportation tunnel project (Underground Construction Report 2022).

Case Study: Laser-Guided Alignment in a 300-Meter Urban Sewer Project

In a congested Barcelona district, contractors installed pipe beneath 15 active roadways using a hybrid system featuring:

- A 635 nm laser transmitter with auto-focus

- Six-axis inclination sensors

- Real-time slurry pressure balancing

Despite encountering unexpected sand lenses, the drive maintained ±12 mm vertical alignment and finished 18 days ahead of schedule. Post-installation surveys confirmed <0.01% deviation from planned coordinates.

Sensor Technology and Data Transmission in Micro Tunneling

Optimal Placement of Inclination, Pressure, and Deflection Sensors

Getting the right placement for these sensors makes all the difference when it comes to keeping alignment within that tight ±25 mm range. We install inclination sensors close to where the cutter head operates so they can pick up even small changes in pitch down to about 0.1 degrees. For sideways movements, we put deflection sensors roughly every two meters along the machine's length. The hydraulic jacks have pressure transducers built in too, which measure how much force is being applied during operation these can handle readings up to 3,000 kN before needing adjustment. According to research published last year by InterfaceForce, companies that got their sensor arrangements just right saw an amazing drop in alignment problems almost 87% fewer issues specifically in those types of soil conditions where everything sticks together.

Wired vs. Wireless Sensor Networks for Reliable Data Relay

For shorter distances under about 200 meters, hardwired connections are still the go to choice because they offer latency below 5 milliseconds. Wireless mesh networks have come a long way though, especially when paired with industrial IoT standards, managing to maintain around 99.7 or 99.8 percent data accuracy even across half a kilometer. Many operators are starting to mix things up these days, using fiber optic lines for the most important steering information while relying on wireless for less critical measurements. The latest Tunneling Automation Report from 2024 shows something interesting too hybrid systems cut down on signal problems by roughly two thirds when compared against purely wired infrastructure in similar conditions.

Evaluating Reliability of Sensor Arrays in Long-Drive Applications

For drives longer than 300 meters, sensors need to last at least 10,000 hours between failures according to industry standards. The housing around MEMS inclination sensors is designed to absorb shocks up to 15g, protecting them from damage. Pressure sensors get tested through 5,000 cycles to ensure durability. Looking at actual field results from 17 cities across different climates, most sensor systems only lose about 2% efficiency after running non-stop for half a year. Take Mumbai's smart sewer system for instance where they implemented backup sensors throughout their network. These setups maintained nearly perfect operation with just 0.05% downtime even when working continuously for 18 hours each day.

Steering Mechanisms and Dynamic Control in Micro Pipe Jacking Machines

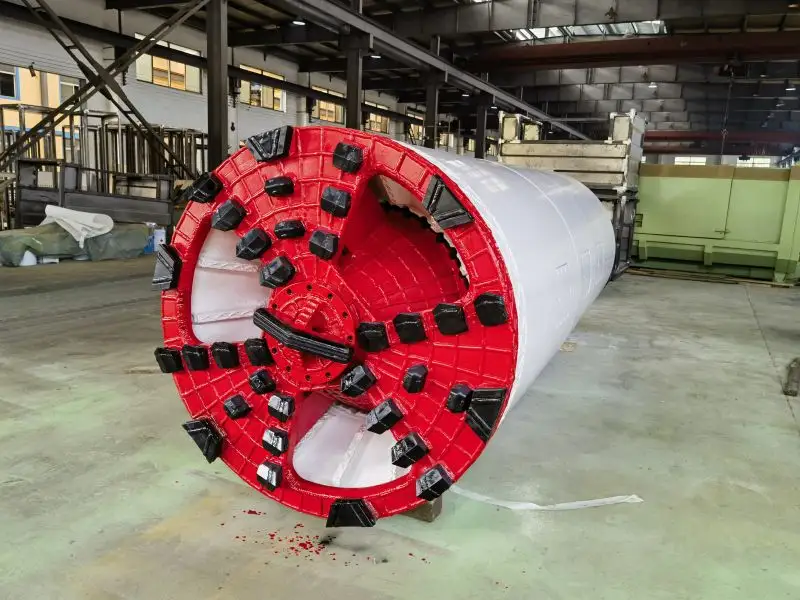

Articulated Cutting Heads for Directional Control

Modern micro pipe jacking machines use articulated cutting heads capable of ±2.5° vertical and horizontal pivoting, enabling precise directional adjustments during excavation. This design allows operators to correct course around underground utilities or obstructions without stopping the jacking process.

Hydraulic Articulation Systems Responding to Real-Time Guidance

Hydraulic actuators linked to PLCs (Programmable Logic Controllers) automatically adjust cutting head orientation based on guidance inputs. A 2023 Trenchless Technology Center study showed these systems respond to steering commands with 98% accuracy within 0.5 seconds, keeping alignment within ±15 mm tolerance zones.

Adjustable Eccentricity in Rotating Cutters for Fine Trajectory Correction

| Correction Method | Adjustment Range | Resolution |

|---|---|---|

| Cutter Eccentricity | 0–50 mm offset | 0.1 mm |

| Rotating cutters with dynamically adjustable centers generate controlled directional bias. This micro-steering capability corrects errors as small as 5 mm over 10-meter spans, making it ideal for maintaining grade in stable, cohesive soils. |

Balancing Machine Rigidity With Steering Flexibility

Advanced jacking machines feature carbon-steel reinforced frames with integrated flex joints, providing structural stability while allowing up to 1.2° of controlled deflection. This balance minimizes ground settlement–typically less than 3 mm in urban settings–while supporting necessary steering adjustments.

From Launch to Reception: Ensuring Alignment Throughout the Jacking Process

Micro pipe jacking maintains alignment accuracy through three rigorously managed phases.

Establishing Reference Points and Calibrating Launch Alignment

Geodetic surveys establish millimeter-precise launch coordinates aligned with project blueprints. Concrete pads with engraved markers are placed at 2-meter intervals near the launch shaft, forming a physical reference grid. Dual-axis inclinometers calibrate cutter head orientation within ±0.2° before jacking begins.

Monitoring Progress and Correcting Deviations During Jacking Cycles

The inclination sensors send out position updates roughly every half minute as work progresses along the line. Operators in control rooms see these trajectory maps in real time on their screens, and get warning signals when things start drifting more than 10 millimeters off track. When this happens, the hydraulic jacks kick in to make small adjustments between 0.5 to 3 degrees across about two sections of pipe, which is typically around 2 to 3 meters long. These corrections help keep things moving forward without losing too much progress. Looking at what's happening in the field right now, most recent construction efforts have hit about 98.7 percent accuracy in maintaining position thanks to these smart PLC systems. They're pretty good at handling those tricky spots where the ground gets harder unexpectedly.

Verifying Final Position at the Reception Shaft

Laser scanners in reception chambers confirm installation accuracy within 24 hours of breakthrough. For drives under 500 meters, final positions typically fall within 0.05% of design alignment when measured with Class 1 survey-grade instruments. As-built documentation compares machine telemetry with manual verification, resolving discrepancies under 5 mm to meet regulatory standards.

FAQ

What is micro pipe jacking?

Micro pipe jacking is a trenchless method for installing pipelines by using specialized machines to push pipes through the ground with precision.

Why is alignment accuracy important in micro pipe jacking?

Alignment accuracy ensures that the pipes are installed correctly without causing disruption to surrounding underground utilities and structures.

What are the common challenges faced in maintaining alignment?

Common challenges include soil variability, buried obstacles, equipment vibration, and groundwater pressure affecting cutterhead steering effectiveness.

How do sensors play a role in micro pipe jacking?

Sensors such as inclination, pressure, and deflection sensors are crucial for monitoring and maintaining alignment accuracy throughout the pipe installation process.

Table of Contents

- The Importance of Alignment Accuracy in Micro Pipe Jacking

- Core Guidance Systems for Real-Time Alignment Control

- Sensor Technology and Data Transmission in Micro Tunneling

- Steering Mechanisms and Dynamic Control in Micro Pipe Jacking Machines

- From Launch to Reception: Ensuring Alignment Throughout the Jacking Process

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY