Geotechnical Data Collection: Foundation for Micro Pipe Jacking Feasibility

The Role of Subsurface Explorations in Early-Stage Feasibility

Before starting any micro pipe jacking work, checking what's beneath the surface matters a lot for spotting geotechnical problems early on. A recent industry report from 2024 found that around three quarters of all project delays come down to unexpected soil issues during excavation, things like hidden rocks or pockets of water sitting above the main groundwater table. Standard Penetration Tests (SPT) and Cone Penetration Tests (CPT) give engineers important numbers about how much weight the ground can hold and how strong it is against sideways forces. This information helps determine where pipes should go. Take soft clay areas where cohesion levels hit over 60 kilopascals as an example. Contractors often need to change course there to avoid ground swelling caused by excessive pushing force. Getting this data upfront lets crews pick the right equipment and lubrication materials ahead of time rather than scrambling mid-project.

Borehole Drilling, Sampling, and In-Situ Testing (SPT/CPT)

The standard practice is to space boreholes between 15 and 30 meters apart along the planned route, taking samples every 1.5 meters vertically to get a good picture of soil variations below ground. Field technicians perform both SPT and CPT tests right there on site to assess how much resistance they might encounter when pushing pipes through the earth, plus they check pore pressures which helps predict what kind of jacking forces will be needed. When working with granular soils like sand or gravel, an SPT value over 50 generally means trouble ahead because it suggests the material will push back harder than expected. These days many crews use wireless CPT equipment that sends readings straight to their tablets while still in the field. This cuts down wait times for results significantly, probably around 40% faster than older methods according to industry reports.

Integrating Remote Sensing and Geophysical Techniques

ERT and GPR technologies give drillers better pictures of what's going on underground by showing how soil properties change sideways over large spaces. Recent research from 2025 shows when engineers pair ERT readings with traditional borehole records, they get about 20% better results figuring out soil layers, which is really helpful where there are lots of pipes and cables hidden beneath city streets. The money saved is pretty impressive too these methods cut down on expenses roughly $14 for every meter drilled compared to just boring holes everywhere. That makes sense because nobody wants to dig up roads unnecessarily while trying to map subsurface conditions accurately.

Soil and Ground Conditions Impacting Micro Pipe Jacking Design

Clay Soils: Behavior Under Thrust and Bore Stress

Clay’s plasticity significantly affects micro pipe jacking efficiency. Swelling pressures under bore stress can demand 10–15% higher thrust capacity than in granular soils. High moisture retention in montmorillonite clays may reduce advance rates by 20–30% (Ponemon 2023), requiring polymer-based lubricants to minimize frictional resistance.

Sandy Strata: Permeability, Stability, and Risk of Collapse

Keeping sandy soils stable really comes down to getting the pressure balance right. When there's more than a 10% deviation from what we call earth pressure equilibrium, problems start showing up as surface settlement issues. Recent findings from a 2024 geotechnical study point out something interesting: almost 4 out of every 10 microtunnel collapses happened specifically in those poorly graded sand areas where the permeability coefficient hits or exceeds 1×10^-3 cm/s. Engineers typically tackle these tricky spots using either pre-grouting techniques or compressed air systems. While effective, implementing these solutions can be quite challenging in practice due to site conditions and material limitations.

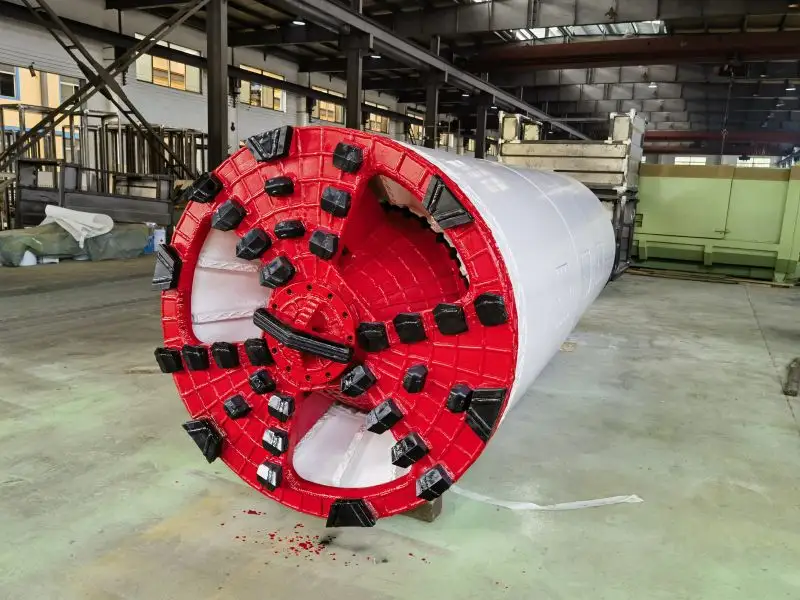

Rocky Ground: Abrasiveness, Equipment Wear, and Advance Rates

Quartz-rich formations accelerate cutting head wear by up to three times compared to shale, reducing daily progress from 12 meters to as low as 4 meters in hard rock. Advanced solutions such as ceramic-coated disc cutters and real-time wear monitoring systems extend tool life by 40% in abrasive conditions.

Comparative Challenges Across Soil Types in Micro Pipe Jacking Projects

| Factor | Clay | Sand | Rock |

|---|---|---|---|

| Thrust Variance | +15% Baseline | ±5% | -10% |

| Contingency Budget | 8–12% | 5–8% | 15–20% |

| Delay Frequency | 42% of projects | 28% of projects | 57% of projects |

While granular soils allow faster advancement, they require rigorous ground support. Cohesive soils offer more predictable deformation but slower progress. Silica-rich rocky layers remain the most costly, with abrasion mitigation accounting for 18–25% of total project budgets.

Geotechnical Baseline Report (GBR) as a Risk Management Tool

Structure and Key Components of a Geotechnical Baseline Report

The Geotechnical Baseline Report, commonly called a GBR, serves as an important contract document that outlines what kind of ground conditions should be expected during micro pipe jacking work. These reports contain all sorts of details including underground profiles, measurements of soil strength, current water table positions, plus warning signs for problems such as abrasive soils or areas prone to collapse. Take for instance when dealing with clay that has a plasticity index exceeding 30 percent or rocks where the uniaxial compressive strength goes beyond 50 MPa mark these situations generally require changing how much force is applied during the jacking process. According to findings from the recent 2024 Trenchless Construction Risk Study published last year, construction teams who actually use proper GBR documentation end up facing around forty percent fewer insurance claims compared to projects that skip this step entirely.

Using GBR to Define and Allocate Ground Risk Between Owner and Contractor

The GBR system basically splits up who's responsible for what risks. Contractors need to keep their costs within certain limits they set at the start, but if something unexpected happens on site, the owner has to cover those extra costs. When looking at borehole reports showing SPT readings between 12 and 18 kN per square meter in sand layers, most contractors will factor this information directly into how they plan their equipment needs. But things get tricky when workers run into hidden obstacles like big rocks that weren't mentioned in surveys or sudden water pressure issues. These situations qualify as differing site conditions under construction law, which means the financial burden moves from the contractor back to the project owner. According to some recent industry stats from ASCE in 2023, this kind of clear division actually stops around two thirds of all arguments over money in pipeline construction projects.

Case Study: Avoiding Cost Overruns with Accurate GBR Application

A 1.2 km microtunneling project in glacial till avoided $2.1 million in overruns by defining baseline permeability (10» para; m/s) and cobble content (¤15%) in its GBR. When isolated zones with seepage rates of 10» acute; m/s were encountered, predefined protocols enabled immediate dewatering without renegotiation, keeping the project within its $8.4 million budget.

When GBR Assumptions Diverge from Field Conditions: Managing Disputes

When actual conditions differ from GBR predictions, a structured resolution process ensures timely action:

- Documentation: Real-time logging of torque, slurry returns, and ground loss

- Third-Party Review: Independent geotechnical engineers verify discrepancies

-

Cost Tracking: Segregated accounting for change-related expenses

Projects using this approach resolve disputes 29% faster than those relying on ad-hoc negotiations, per a 2023 industry analysis.

Translating Ground Data into Design and Cost Models for Micro Pipe Jacking

From Soil Logs to Unit Rate Adjustments in Project Budgeting

Geotechnical reports directly influence cost modeling by linking soil behavior to construction challenges. While cohesive soils require lower jacking forces, they increase lubrication needs. Sandy strata necessitate stabilization measures that raise line-item costs by 12–18% (industry benchmarks 2023). Detailed borehole log analysis enables unit rate adjustments for:

- Material wear: Abrasive soils reduce cutter head lifespan by 30–50%

- Labor productivity: Silty layers slow advance rates to 1.2 m/day versus 3.5 m/day in uniform gravels

- Risk premiums: Fractured rock zones trigger 15% contingency uplifts

This data-driven method prevents budget shortfalls, as demonstrated in a recent instrumentation study comparing predicted and actual costs across 17 micro pipe jacking projects.

Impact of Unforeseen Ground Conditions on Contingency Planning

When field conditions deviate from geotechnical baselines, 42% of projects exceed contingency allowances within 45 days. A 2023 survey of municipal contractors showed that unanticipated groundwater inflows lead to:

| Scenario | Cost Impact | Schedule Delay |

|---|---|---|

| Sand boiling | +28% | 22 days |

| Cobble obstruction | +19% | 14 days |

| Chemical contamination | +37% | 31 days |

Best practices now recommend allocating 10–25% contingency based on ground risk severity tiers defined in GBRs.

Emerging Trends: Digital Twin Simulations for Predictive Costing

Advanced modeling tools use digital twin technology to generate iterative cost scenarios by integrating soil data with real-time jacking parameters. One leading contractor reduced redesign costs by 63% after implementing a system that:

- Simulates annular grout flow under varying ground pressures

- Predicts torque fluctuations in mixed-face geology

- Automates cost recalculations when encountering unexpected strata

These systems enable dynamic budget adjustments, minimizing contingency waste while maintaining 99% bore path accuracy in complex ground conditions.

FAQ

Why is subsurface exploration crucial before starting micro pipe jacking?

Subsurface exploration helps identify potential geotechnical issues like hidden rocks or water pockets early, which helps in avoiding project delays during excavation.

What tests are typically performed during geotechnical data collection?

Standard Penetration Tests (SPT) and Cone Penetration Tests (CPT) are usually conducted to gather data about soil strength and load-bearing capacity.

How can unforeseen ground conditions impact a micro pipe jacking project?

Unexpected ground conditions can lead to significant cost overruns and schedule delays if not adequately managed and accounted for in contingency planning.

What role does a Geotechnical Baseline Report play?

A GBR outlines expected ground conditions and helps manage risks by clearly defining responsibilities between project owners and contractors.

How do digital twin simulations help in micro pipe jacking projects?

Digital twin simulations predict possible cost scenarios and help in making dynamic budget adjustments, thus reducing redesign costs and improving project outcome accuracy.

Table of Contents

- Geotechnical Data Collection: Foundation for Micro Pipe Jacking Feasibility

- Soil and Ground Conditions Impacting Micro Pipe Jacking Design

- Geotechnical Baseline Report (GBR) as a Risk Management Tool

- Translating Ground Data into Design and Cost Models for Micro Pipe Jacking

-

FAQ

- Why is subsurface exploration crucial before starting micro pipe jacking?

- What tests are typically performed during geotechnical data collection?

- How can unforeseen ground conditions impact a micro pipe jacking project?

- What role does a Geotechnical Baseline Report play?

- How do digital twin simulations help in micro pipe jacking projects?

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY