What Is a Micro TBM? Core Components and Key Differences

Definition and core components of Micro TBM

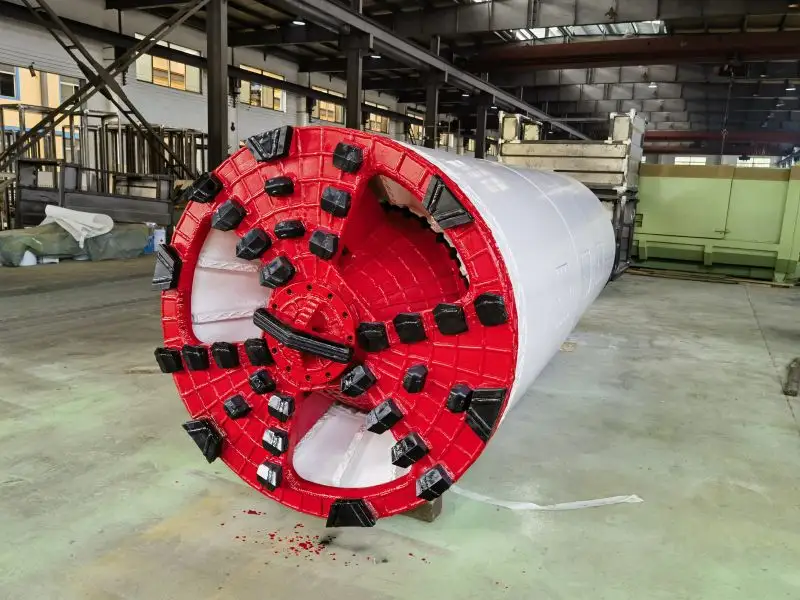

The Micro Tunnel Boring Machine, commonly called TBM, works best when digging tunnels smaller than 1.5 meters across. These machines come equipped with several key parts including a spinning cutting head that digs through dirt, hydraulics that push it forward, and either wet or dry systems to handle all the excavated material. What really sets them apart though is their laser guidance system, which keeps everything aligned within fractions of a centimeter. According to industry reports from 2023, this kind of precision cuts down on alignment problems by around 15% compared to older manual techniques. Municipalities love these TBMs especially for laying pipes and cables underneath busy streets without tearing up roads or disrupting daily life above ground level.

How Micro TBMs differ from conventional TBMs

Conventional tunnel boring machines work best for big tunnels over 6 feet wide, but Micro TBMs are designed specifically for tight spots where space is limited. The older versions need massive entry points and lots of workers on site at all times. Micro TBMs can be controlled from a distance though, and they actually incorporate pipe installation right as they dig through the ground. According to Realtop Machinery research from last year, projects using these smaller machines finish anywhere between 25% to almost 40% faster in crowded city areas. Plus, their modular construction means crews can take them apart quickly when needed and move them to different job locations something that just isn't possible with those larger traditional machines sitting around taking up space.

Functionality and control systems in micro tunnel boring machines

The latest generation of Micro TBMs are equipped with smart sensors connected through the Internet of Things, which track things like torque levels, thrust force, and how much resistance they encounter from different types of soil as they work underground. The machines send all this information back to people working on the surface in real time. Some clever computer programs can actually figure out when parts might fail well ahead of schedule sometimes as much as 50 hours before anything goes wrong according to industry reports from 2023. That kind of foresight cuts down unexpected stoppages by around 30%. For dealing with tricky ground conditions, these machines have special closed loop systems that keep everything balanced properly. And there's also built-in camera systems giving workers full view all around the tunnel being dug, helping them avoid any potential collisions. All these features allow for non-stop operation at pretty impressive rates too, pushing forward about 15 meters each day without putting surrounding structures at risk.

Precision and Automation: The Technological Edge of Micro TBM

Automated Guidance Systems in Micro TBM Operations

The micro TBMs rely on automated guidance systems that bring together inertial navigation tech, tilt sensors, plus hydraulic steering mechanisms to hit those super precise measurements down to the millimeter. What makes these systems so effective is their ability to tweak the cutterhead position anywhere from 50 to 100 times every single second, which pretty much wipes out the mistakes people tend to make when trying to align things manually. The numbers tell the story too – we're seeing about a 40% drop in alignment issues. This matters a lot for digging tunnels under delicate spots in cities where there are old buildings standing or existing metro lines running below ground level. Engineers can sleep better knowing the machines won't drift off course and damage valuable infrastructure during operations.

Laser-Based and CCTV Guidance for Real-Time Accuracy

Using dual coordinate lasers along with those PTZ style security cameras gives workers instant spatial info they can act on right away when adjustments are needed. The laser basically serves as an anchor point on the cutting head, whereas the cameras check what's actually happening versus what shows up in the digital plans. When installing fiber optic lines through Londons old neighborhoods back in 2023, these systems kept ground movement below just 3 millimeters. That kind of precision was absolutely essential since there were centuries old buildings sitting directly over where the tunnels ran.

IoT Integration for Real-Time Monitoring and Data Analytics

Micro TBMs come packed with around 30 to 50 IoT sensors built right into them, sending all sorts of operational info like torque levels, thrust measurements, and what kind of soil they're digging through up to cloud storage systems. This lets engineers tweak the drilling setup while the machine is actually running, which helped boost progress speeds by roughly 22 percent when working on those big wastewater tunnels under New York City. The real magic happens with machine learning algorithms that look at rock formations and soil types, then suggest just the right RPM settings and slurry pressure adjustments needed for different ground conditions. What this means in practice is smoother operations and fewer stoppages as crews navigate through tricky underground environments.

AI-Powered Predictive Maintenance for Operational Continuity

Looking at how machines vibrate and checking the condition of hydraulic fluids helps AI systems spot when equipment might fail somewhere between 300 to 500 hours ahead of time. The ability to predict these issues cuts down on unexpected stoppages by around two thirds, which is really important for city construction jobs where there are tight rules about noise levels and working hours. Take one metro area telecom project last year as an example. Their AI system caught signs that a main bearing was starting to wear out during those regular nighttime inspections they do. Without this early warning, the whole operation could have faced a massive 14 day setback.

Innovations Driving Modern Microtunneling Machinery

Advanced Cutterhead Designs for Diverse Geological Conditions

The latest Micro TBM cutterhead designs come with modular setups that let operators adjust cutting angles as needed, plus they have replaceable disc cutters which cut down on wear by around 40% when working through those tricky mixed soil and rock conditions. This is a big improvement over older fixed design models according to Tunneling Journal from last year. What makes these machines really stand out though are their dual mode capabilities. They can switch instantly from handling soft ground to tackling hard rock formations without needing to stop operations at all. This kind of flexibility is absolutely critical when digging tunnels under city streets where the underground layers just never seem to stay consistent from one spot to another.

Hybrid and Energy-Efficient Power Systems for Sustainability

Leading manufacturers now deploy hybrid diesel-electric powertrains that cut fuel consumption by 28% while sustaining high torque output. Regenerative braking captures kinetic energy during deceleration and repurposes it for auxiliary functions like slurry pumping. These advancements align with global decarbonization goals, reducing CO₂ emissions by 22 tons per kilometer excavated.

Remote Operation Capabilities Enhancing Precision and Safety

With AI at the controls, operators can now run every aspect of Micro TBM operations right from their surface stations without needing to go down into the tunnels themselves. The system constantly monitors what's happening underground through real time data coming back from sensors. This lets it tweak things like how much pressure is applied during thrusting and how fast the cutting head spins around. According to recent studies from NIOSH in 2024, these adjustments help achieve almost perfect alignment when laying fiber optic cables - getting within just 0.4% of perfect straightness. Getting workers out of those dangerous underground areas cuts their risk of injury significantly too. Statistics show we're talking about a reduction of roughly three quarters in exposure to harmful conditions, which goes a long way toward solving many of the safety issues that keep OSHA busy regulating throughout the tunneling industry.

Integration of Smart Controls in MTBM Workflows

Control panels that can diagnose themselves are now using machine learning algorithms to look at more than 200 different operating factors. These systems can actually predict when something might fail as much as 80 hours ahead of time. For underground construction work, automated grouting setups work hand in hand with how fast digging happens through pressure monitoring devices. This helps keep buildings from sinking too much especially where there's lots of clay in the ground. The numbers tell quite a story too since early 2022. Cities packed with people have seen their projects delayed less often now that these intelligent processes are in place. We're talking about cutting down those frustrating delays by around 34 percent across major metropolitan areas.

Applications in Urban Infrastructure: Efficiency with Minimal Disruption

Key Urban Applications of Micro TBM Technology

Micro TBM technology is widely used to install critical subsurface infrastructure with minimal surface impact. Primary applications include:

- Utility tunnels for water, sewage, and electrical networks

- Stormwater drainage systems to mitigate urban flooding

- Telecom conduit networks supporting 5G expansion

- Gas pipeline installations beneath heritage zones

Their compact size (0.6−1.5m diameter) allows navigation beneath roads and buildings, avoiding disruptive open-cut excavation or structural underpinning.

Time Efficiency in Congested City Environments

In Madrid’s telecom network expansion, Micro TBMs completed 2.1km of tunneling 40% faster than open-cut techniques by operating continuously without surface interference. Industry data shows urban Micro TBM projects finish 30–50% quicker than drill-and-blast methods (Urban Tunneling Journal 2023), making them ideal for cities aiming to minimize public inconvenience.

Precision Engineering to Minimize Surface Disruption

With positional accuracy within ±5mm, Micro TBMs enable highly controlled tunneling, including:

- Safe passage under operational metro lines with less than 1mm of ground settlement

- Installation of 800mm pipelines at depths of 8m beneath busy highways

- Navigation through tight curves with radii as small as 30m

This precision results in 70% less surface disturbance than traditional methods, preserving existing landscapes while upgrading underground utilities.

Case Examples: Utility Tunnels, Stormwater Systems, and Telecom Networks

The city of Tokyo put into action 12 small tunnel boring machines called Micro TBMs for installing about 23 kilometers worth of underground sewer pipes beneath layers of soil reaching down around 15 meters in depth. Remarkably, they managed to finish this massive job without causing any major disruptions to daily life in their sprawling metropolis home to over 14 million people. Meanwhile across the pond in London, engineers worked with one particular Micro TBM measuring just 0.9 meters across which managed to dig forward at an impressive rate of 15 meters per day right through those old Victorian building foundations. This helped avoid what would have been six whole weeks of necessary but annoying road closures. Looking at these real world examples shows clearly why many cities are turning to these compact tunneling solutions when upgrading their infrastructure needs without tearing up streets and inconveniencing residents.

Cost, Safety, and Environmental Benefits of Micro TBM Use

Micro TBM technology delivers 30% lower operational costs for small-diameter projects (€1.5m), with completion times reduced by 40% in urban settings (2023 Tunneling Cost Analysis). Savings stem from precise material usage and reduced labor demands—projects typically require 60% fewer personnel than drill-and-blast operations.

Compared to traditional methods, Micro TBMs offer significant advantages:

- 85% reduction in vibration, protecting adjacent structures

- 92% drop in particulate emissions (Ponemon Institute 2023)

- Surface disruption zones shrink from 15m² to just 2m²;

Environmentally, Micro TBM projects generate a 45% lower carbon footprint due to efficient energy use and 98% reduced spoil volume. The closed-loop excavation system prevents groundwater contamination—especially important when working beneath protected aquifers.

Safety performance is markedly improved, with 73% fewer worksite accidents attributed to remote operation and automated pressure control. These systems eliminate worker exposure to tunnel faces and reduce collapse risks by 68%.

Long-term benefits include extended equipment life—AI diagnostics increase component longevity by 30%—and high reusability, with modular designs allowing 85% of parts to be reused across projects. Together, these factors contribute to 22% higher project completion rates in multi-year urban infrastructure programs.

FAQ Section

What is a Micro TBM?

A Micro Tunnel Boring Machine (TBM) is used for small-diameter tunneling projects, ideal for digging tunnels smaller than 1.5 meters across.

How does a Micro TBM differ from conventional TBMs?

Micro TBMs are designed for tight spaces and can be controlled remotely. They are compact and modular, unlike conventional TBMs that require large entry points and more on-site workers.

What are the core components of a Micro TBM?

Core components include a spinning cutting head, hydraulic push mechanisms, laser guidance systems, and systems to handle excavated material.

What are the advantages of using Micro TBMs?

Micro TBMs offer precision, faster project timelines, reduced labor needs, environmental benefits like lower carbon footprint, and improved safety due to remote operation capabilities.

What are common urban applications for Micro TBMs?

Micro TBMs are used for utility tunnels, stormwater systems, telecom networks, and gas pipelines installation with minimal surface disruption.

Table of Contents

- What Is a Micro TBM? Core Components and Key Differences

- Precision and Automation: The Technological Edge of Micro TBM

- Innovations Driving Modern Microtunneling Machinery

- Applications in Urban Infrastructure: Efficiency with Minimal Disruption

- Cost, Safety, and Environmental Benefits of Micro TBM Use

- FAQ Section

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY