Geological and Geotechnical Conditions Influencing Tunnel Drilling Machine Selection

Assessing soil, rock composition, and ground stability

Tunnel Boring Machines (TBMs) require precise geological compatibility to operate efficiently. A 2023 study in Scientific Reports found that 70% of TBM downtime stems from geological incompatibility, particularly in mixed soil environments. Key considerations include:

- Abrasive rock layers causing 3 faster cutterhead wear compared to soft soils

- Clay-rich formations requiring enhanced torque capacity to prevent machine stalling

- Fractured zones demanding real-time ground support adjustments to avoid collapses

Evaluating groundwater pressure and fault zones

Groundwater pressures exceeding 5 bar can compromise tunnel integrity, while fault zones increase collapse risks by 40%. Modern TBMs integrate:

- Hyperbaric pressure sensors for immediate water ingress detection

- Grouting systems activated at 3 bar differential pressure thresholds

- Seismic pre-screening modules to map fault lines within 15 meters of the bore path

Case study: Adapting TBMs to complex geology in the Gotthard Base Tunnel

The Gotthard project confronted 73 distinct geological interfaces, including:

- Meta-sedimentary rock sections requiring 450 kN thrust capacity

- Phreatic water zones managed through dual-stage dewatering

- Shear zones mitigated via modular segmental lining systems

This adaptation reduced geological delays by 62% compared to conventional methods, demonstrating the critical role of comprehensive geotechnical investigation in tunnel drilling machine selection.

Matching Tunnel Boring Machine Types to Ground Conditions

Selecting the optimal tunnel boring machine (TBM) requires aligning machine capabilities with subsurface challenges.

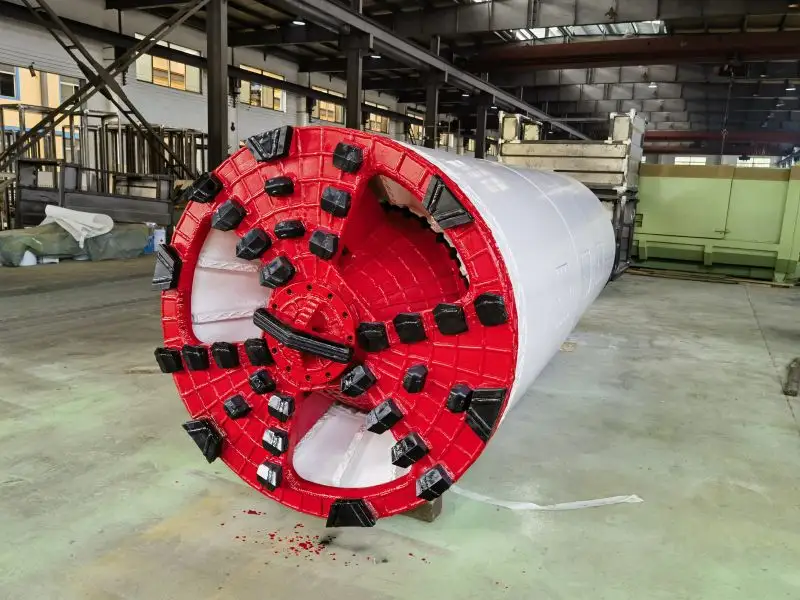

EPB, Slurry, and Hard Rock TBMs: Choosing Based on Geology

Earth Pressure Balance (EPB) Tunnel Boring Machines perform best in soft soils and city settings where they use compressed earth material to keep tunnel walls stable while keeping surface movement to a minimum. When dealing with saturated ground conditions, slurry shield machines take over because they mix bentonite clay with water to create a slurry that balances against groundwater pressure from below. Hard rock TBMs equipped with disc cutters can make good progress through solid rock formations at around 15 to maybe even 30 meters per day depending on rock quality. According to a recent study published in 2022, when engineers pick the wrong type of machine for specific geological conditions, projects tend to get delayed by roughly two thirds longer than expected. This highlights how important it is to really understand what lies beneath before starting excavation work.

Multimodal TBMs for Variable and Heterogeneous Ground Conditions

Modern hybrid tunnel boring machines combine both EPB and slurry technologies, allowing them to handle different rock types without stopping the entire project. Take the Gotthard Access Tunnel as an example case study. There, engineers used a machine that could switch modes multiple times during excavation. Specifically, it changed settings around 14 separate instances while working through layers of limestone mixed with softer marl deposits. These machines come equipped with sensors that constantly monitor what's happening underground. When they detect changes in the ground ahead, the system adjusts things like torque and thrust automatically. This has led to roughly a 40% drop in unexpected halts when dealing with tricky mixed face conditions. Another big plus comes from modular cutterhead designs. Instead of taking weeks to swap out tools for different rock formations, crews can now complete these changes in just about two days flat, which makes a huge difference in keeping projects on schedule.

Tunnel Dimensions, Alignment, and Machine Performance Requirements

Impact of Tunnel Depth, Diameter, and Alignment on TBM Choice

How deep a tunnel goes determines the ground pressure it experiences, which means tunnel boring machines need extra strong construction to handle pressures over 5 bar when digging really deep underground. The size matters too. Big machines over 12 meters across usually work best with earth pressure balance systems in city environments where we don't want buildings sinking down. Smaller ones under 6 meters can get away with guided boring tech for precise positioning. When tunnels curve or go straight up/down, operators need machines that can bend and twist quite a bit - around 8 degrees of turning ability helps them manage those tricky elevation shifts without breaking apart. Recent studies looking at rectangular shaped tunnel ends showed something interesting. If the height is more than 1.5 times wider, there's about a 34% higher chance of instability problems forming. That explains why engineers spend so much time designing cutting heads that match specific tunnel paths.

Power, Thrust, and Advance Rate Optimization for Project Efficiency

Today's tunnel boring machines need somewhere between 2,500 to 6,000 kilonewtons of thrust force just to keep moving forward at decent speeds of around 15 to 35 millimeters per minute when dealing with mixed ground conditions. The power systems have to be sized right for the torque requirements of the cutting head, which usually range from 3 to 15 meganewton meters. When working through hard rock formations, the disc cutters typically spin at about 5 to 6 revolutions per minute powered by 350 kilowatt motors. Things change quite a bit when we look at earth pressure balance machines operating in softer soils. These machines focus more on managing the spoil removal process, so they rely heavily on the torque capacity of their screw conveyors, generally needing between 120 and 250 kilonewton meters. Some interesting findings from work done in soft soil tunneling back in 2015 showed that making real time adjustments to the thrust pressure can cut down on directional errors by nearly half compared to sticking with fixed pressure settings. Tunnel operators always walk a fine line between how fast they want to push through the ground and how long their tools will last. Recent studies from 2022 indicate that simply lowering the RPM by 20% can actually double the lifespan of cutters working through really abrasive granite formations.

Technology Integration and Operational Efficiency in Modern Tunnel Drilling Machines

Modern tunnel drilling machines (TDMs) now feature automation and AI-assisted guidance systems that optimize excavation accuracy while reducing human error. Real-time monitoring tools embedded in these systems analyze geological data to adjust cutterhead torque and thrust forces dynamically, ensuring alignment precision within ±10mm even in unstable strata.

Automation, AI-Assisted Guidance, and Real-Time Monitoring Systems

Modern AI systems can handle over 500 sensor readings every single second, allowing them to forecast how the ground will behave and tweak drilling settings accordingly. This has actually cut down unexpected stoppages by about a quarter in major projects such as the Gotthard Base Tunnel construction. When it comes to managing slurry, automation keeps pressure levels balanced, which helps prevent collapses when working through wet soil conditions. Real time monitoring setups have proven really effective too, cutting water seepage problems by around 40 percent when compared to old school manual techniques. And let's not forget about those predictive maintenance features that keep equipment running longer, extending parts life by roughly 30% according to field reports from several engineering firms.

Remote Diagnostics and Control Systems for Enhanced Performance

Centralized control hubs now enable remote TBM operation using IoT-enabled diagnostics. For example, vibration analysis algorithms detect bearing wear 50 hours before failure, allowing preemptive repairs. A 2024 pilot project using remote guidance systems achieved 98% uptime in urban pipeline installations by streamlining cutter changes and spoil removal.

| Feature | Traditional TDMs | Modern Tech-Integrated TDMs |

|---|---|---|

| Alignment Accuracy | ±50mm | ±10mm |

| Failure Detection | Manual inspections | AI-driven predictive alerts |

| Daily Advance Rate | 15–20 meters | 25–35 meters |

These advancements cut project timelines by 20–30% while lowering labor costs and safety incidents.

Total Cost of Ownership, Maintenance, and Workforce Adaptability

Lifecycle Costs, Maintenance Needs, and Repair Accessibility

A tunnel drilling machine’s total cost of ownership (TCO) extends far beyond its initial price, with operations and maintenance (O&M) accounting for 45–60% of lifetime expenses. This includes:

- Periodic maintenance: Cutterhead inspections ($12k–$18k per interval) and seal replacements ($740k–$2.1M annually) to prevent catastrophic failures

- Unscheduled repairs: Wear part replacements in abrasive rock conditions, costing up to 30% of annual project budgets

- Downtime impacts: 1–2 week delays from bearing failures reduce tunneling efficiency by 18–22%

Repair accessibility drives 25% of maintenance costs in confined workspaces. Modular designs with standardized components reduce component replacement time by 40% compared to custom systems.

Operator Training, Safety Features, and Compliance With Local Regulations

Skilled operators improve advance rates by 15% while reducing cutter tool wear by 28%. Mandatory certifications now require:

- 120–180 hours of simulator training for soft-ground TBM operations

- Weekly safety drills covering fire suppression and emergency evacuation

- Compliance with regional standards like OSHA’s confined space entry protocols (29 CFR 1926.800)

Modern tunnel drilling machines integrate collision avoidance systems (25% fewer incidents) and automated gas monitoring to meet EU Machinery Directive 2023 updates. A 2023 project in Central Europe demonstrated that adaptive training programs reduced unplanned downtime by 30% through real-time performance analytics.

FAQ

What are the key factors influencing Tunnel Boring Machine (TBM) selection?

Key factors include geological compatibility such as rock composition, soil type, ground stability, groundwater pressure, and fault zone presence, which can impact the machine's efficiency and the project's overall success.

How do modern TBMs handle variable ground conditions?

Modern Tunnel Boring Machines, particularly hybrid models, integrate both Earth Pressure Balance (EPB) and slurry technologies to adapt to different rock types, using real-time sensors for monitoring and automatic adjustments.

Why is technology integration important in TBMs?

Technology integration like AI-assisted guidance systems and real-time monitoring improves precision in excavation, reduces human error, and enhances overall operational efficiency by adjusting cutterhead settings dynamically for exact alignment.

What training is required for TBM operators?

Operators are generally mandated to have 120-180 hours of simulator training, undergo weekly safety drills, and comply with regional safety standards such as OSHA's confined space entry protocols to ensure efficient and safe TBM operations.

Table of Contents

- Geological and Geotechnical Conditions Influencing Tunnel Drilling Machine Selection

- Matching Tunnel Boring Machine Types to Ground Conditions

- Tunnel Dimensions, Alignment, and Machine Performance Requirements

- Technology Integration and Operational Efficiency in Modern Tunnel Drilling Machines

- Total Cost of Ownership, Maintenance, and Workforce Adaptability

- FAQ

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY