Understanding Modern Underground Pipe Installation Methods

The construction and maintenance of underground infrastructure have evolved significantly over the years, with no-dig solutions emerging as a revolutionary approach to pipe installation and repair. These innovative techniques have transformed how we handle underground piping projects, offering remarkable benefits that traditional open-cut methods simply cannot match. As cities expand and infrastructure ages, the demand for efficient, cost-effective, and environmentally conscious solutions continues to grow.

No-dig solutions represent a suite of advanced technologies that allow for the installation, replacement, or repair of underground pipes with minimal surface disruption. This methodology has gained tremendous popularity among municipalities, contractors, and property owners who seek to maintain their underground infrastructure while minimizing environmental impact and community disruption.

Environmental Benefits of No-Dig Technology

Reduced Carbon Footprint

No-dig solutions significantly decrease the environmental impact of underground piping projects. Traditional excavation methods require heavy machinery operating for extended periods, consuming substantial amounts of fuel and releasing emissions. In contrast, no-dig techniques utilize smaller equipment and require fewer vehicle movements, resulting in a marked reduction in carbon emissions.

The preservation of existing landscapes and vegetation is another crucial environmental advantage. When contractors employ no-dig solutions, they avoid the widespread disruption of soil structures and root systems that typically occurs during conventional excavation. This protection of natural ecosystems helps maintain urban greenery and supports local biodiversity.

Soil Conservation and Groundwater Protection

Traditional trenching methods often disturb soil composition and can lead to erosion problems. No-dig solutions maintain soil integrity by minimizing ground disturbance. This preservation of soil structure is particularly important in areas with sensitive geological conditions or where soil stability is crucial for surrounding structures.

The technique also helps protect groundwater resources by reducing the risk of contamination. With minimal excavation required, there's less chance of disturbing existing contaminated soil or creating pathways for surface pollutants to reach groundwater supplies.

Economic Advantages of No-Dig Implementation

Cost Reduction Through Efficiency

The financial benefits of no-dig solutions are substantial and multifaceted. Project costs are significantly reduced due to decreased labor requirements, shorter completion times, and minimal restoration needs. Traditional excavation methods often require extensive surface restoration, including repaving roads and rebuilding sidewalks, which can account for a substantial portion of project budgets.

Equipment and material costs also tend to be lower with no-dig solutions. While the specialized equipment may have a higher initial investment, the overall project costs are typically reduced due to faster completion times and fewer required resources. Additionally, the precision of no-dig techniques often results in less material waste.

Business Continuity Benefits

One of the most significant economic advantages of no-dig solutions is the minimal disruption to business operations. Traditional excavation methods can force businesses to close or restrict access during construction, resulting in lost revenue. No-dig techniques allow businesses to maintain normal operations, preventing costly interruptions and maintaining customer access.

The reduction in project duration also translates to faster return on investment for infrastructure improvements. Projects that might take weeks or months using conventional methods can often be completed in days using no-dig solutions, allowing for quicker implementation of system upgrades and repairs.

Technical Superiority of No-Dig Methods

Advanced Equipment and Precision

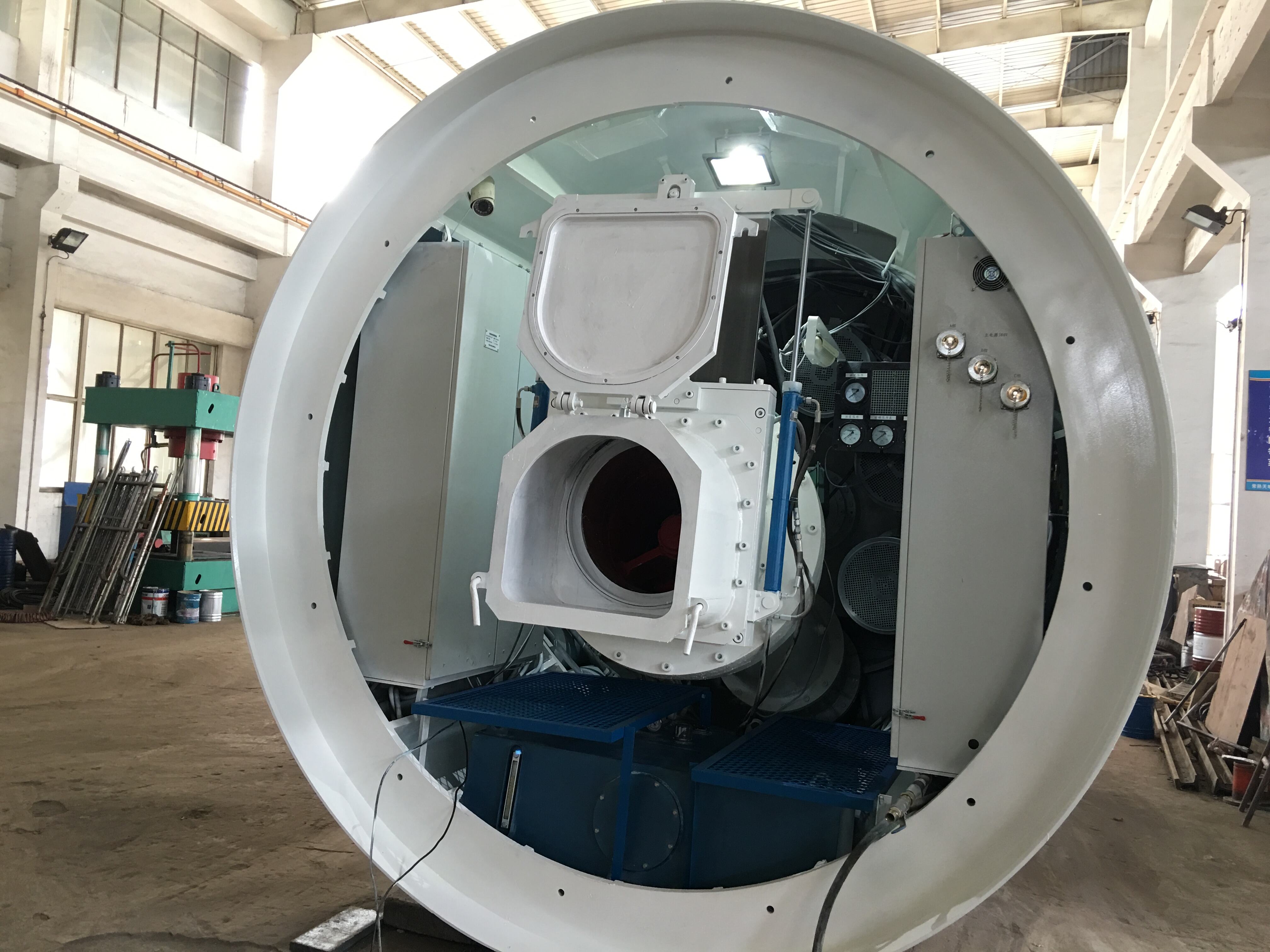

No-dig solutions utilize state-of-the-art technology that provides unprecedented accuracy in pipe installation and repair. Modern equipment includes sophisticated guidance systems, allowing operators to navigate complex underground pathways with remarkable precision. This technical advantage ensures optimal pipe placement and minimizes the risk of damaging existing utilities.

The technology behind no-dig solutions continues to evolve, with new innovations regularly emerging. These advancements include improved materials, more efficient boring techniques, and enhanced monitoring systems that provide real-time data during installation processes.

Versatility in Application

The adaptability of no-dig solutions makes them suitable for a wide range of applications and soil conditions. These methods can be used for installing new pipes, replacing damaged ones, or rehabilitating existing infrastructure. The technology works effectively in various soil types and can navigate around existing utilities and obstacles with minimal risk.

Different no-dig techniques can be employed depending on project requirements, including horizontal directional drilling, pipe bursting, and slip lining. This versatility ensures that contractors can select the most appropriate method for each specific situation, optimizing project outcomes.

Social Impact and Community Benefits

Minimized Public Disruption

One of the most appreciated aspects of no-dig solutions is their minimal impact on daily community life. Traditional excavation methods often result in road closures, traffic diversions, and noise pollution that can last for weeks or months. No-dig techniques significantly reduce these disruptions, allowing communities to maintain their normal routines with minimal inconvenience.

The reduction in noise and dust pollution is particularly beneficial in urban areas where construction activities can significantly impact quality of life. No-dig solutions help maintain cleaner air quality and quieter environments during infrastructure work.

Safety Improvements

Worker safety is enhanced through no-dig solutions, as they minimize the need for personnel to work in deep trenches. This reduction in confined space work significantly decreases the risk of accidents and injuries commonly associated with traditional excavation methods.

Public safety is also improved, as there are fewer open excavations that could pose risks to pedestrians and vehicles. The reduced presence of heavy machinery and construction vehicles on public roads further enhances community safety during infrastructure projects.

Frequently Asked Questions

How long do no-dig pipe installations typically last?

No-dig pipe installations, when properly executed, typically have a service life of 50 to 100 years, depending on the materials used and environmental conditions. Modern pipe materials and installation techniques ensure exceptional durability and longevity, often exceeding the lifespan of traditionally installed pipes.

Can no-dig solutions be used in all soil types?

While no-dig solutions are highly versatile, their effectiveness can vary depending on soil conditions. Most soil types are suitable for no-dig techniques, but particularly challenging conditions such as loose sand or solid rock may require specific equipment or modified approaches. Professional assessment of soil conditions is essential for selecting the most appropriate no-dig method.

What is the maximum depth for no-dig pipe installation?

The maximum depth for no-dig installations varies depending on the specific technique used and local ground conditions. However, most no-dig methods can easily reach depths of 20-30 feet, with some specialized equipment capable of installations at even greater depths. The key factor is maintaining accurate guidance and control throughout the installation process.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY