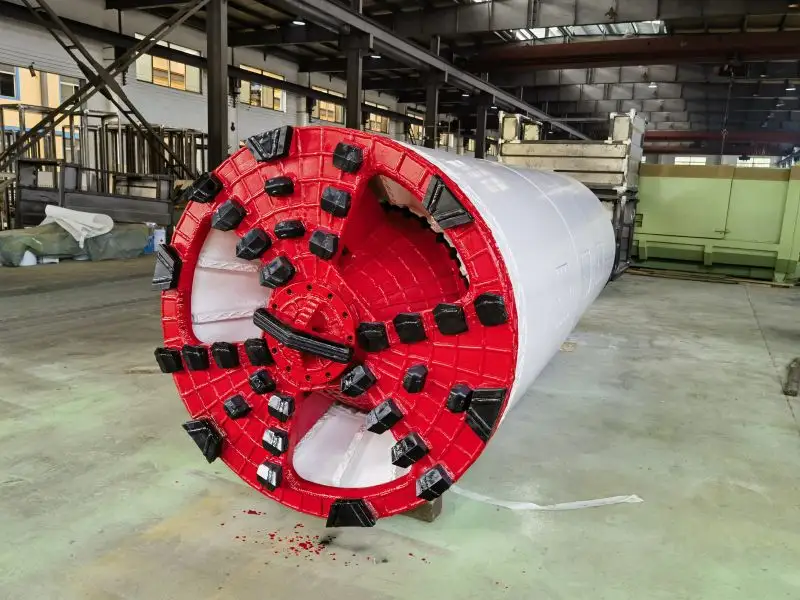

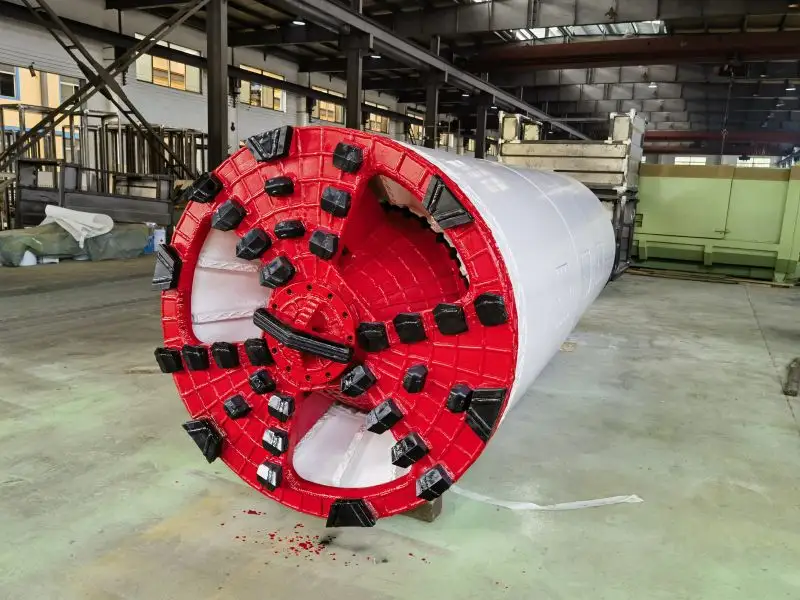

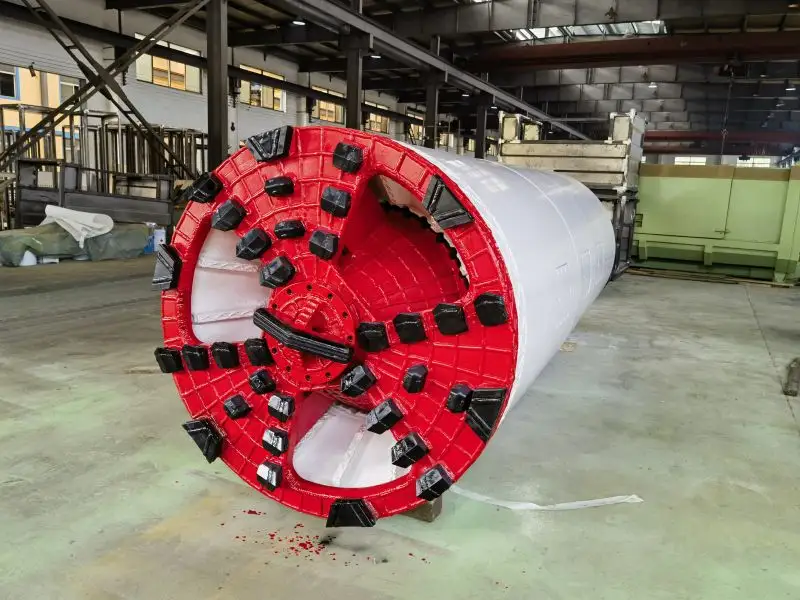

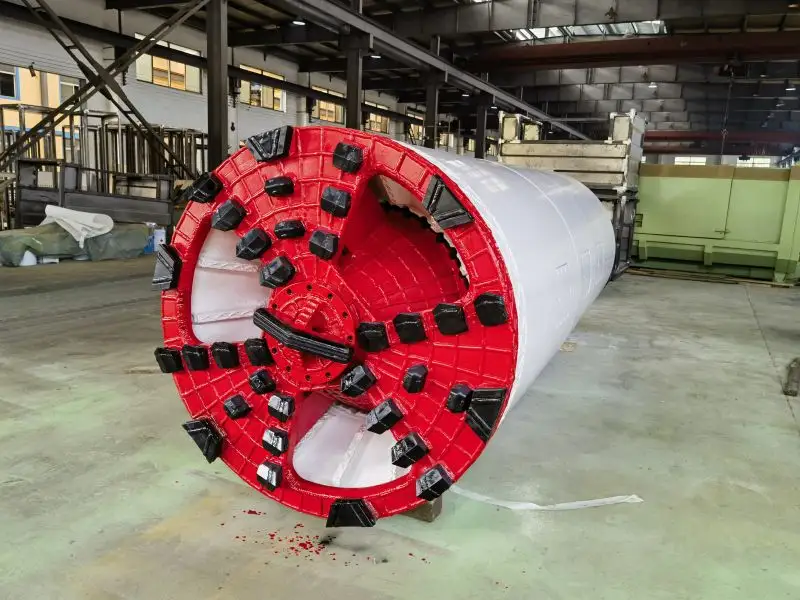

Hiểu về Máy Ép Ống Cân Bằng Áp Lực Đất và Vai Trò của Chúng trong Xây Dựng Không Đào Hào. Máy Ép Ống Cân Bằng Áp Lực Đất (EPB) là gì? Máy ép ống cân bằng áp lực đất (EPB) hoạt động như một hệ thống khoan hầm thực hiện hai nhiệm vụ...

Xem Thêm

Thu Thập Dữ Liệu Địa Kỹ Thuật: Cơ Sở cho Khả Thi của Phương Pháp Ép Ống Vi Mô. Vai Trò của Khảo Sát Dưới Mặt Đất trong Giai Đoạn Khả Thi Ban Đầu. Trước khi bắt đầu bất kỳ công việc ép ống vi mô nào, việc kiểm tra những gì nằm dưới bề mặt rất quan trọng để nhận diện các yếu tố địa kỹ thuật...

Xem Thêm

Các Thành Phần Chính và Khả Năng Tùy Chỉnh của Máy Đẩy Ống Cân Bằng Bùn Máy Đẩy Ống Cân Bằng Bùn Là Gì? Máy đẩy ống cân bằng bùn là các hệ thống đào hầm không rãnh, duy trì sự ổn định dưới lòng đất bằng cách sử dụng một lớp bùn áp lực trước...

Xem Thêm

Đánh Giá Điều Kiện Đất Và Mặt Bằng Để Hướng Dẫn Lựa Chọn Máy Khoan Vi Mô Vai Trò của Khảo Sát Địa Kỹ Thuật trong Thiết Kế Khoan Vi Mô Việc đạt được kết quả tốt từ khoan vi mô bắt đầu với các khảo sát địa kỹ thuật chính xác. Trước khi lựa chọn...

Xem Thêm

Máy Micro Tunneling Là Gì và Cách Nó Hoạt Động Như Thế Nào? Máy micro tunneling, hay còn gọi tắt là MTM, là các hệ thống điều khiển từ xa được thiết kế đặc biệt để lắp đặt đường ống ngầm mà không cần đào hào. Những máy này khoan...

Xem Thêm

Micro TBM Là Gì? Các Thành Phần Chính và Điểm Khác Biệt Chính Định nghĩa và các thành phần chính của Micro TBM Máy khoan hầm vi mô, thường được gọi là TBM, hoạt động hiệu quả nhất khi đào các hầm có đường kính nhỏ hơn 1,5 mét. Những máy này được trang bị...

Xem Thêm

Tầm Quan Trọng của Độ Chính Xác trong Việc Cân Chỉnh khi Đẩy Ống Viễn Khả Thi Vai Trò của Độ Chính Xác trong Việc Lắp Đặt Đường Ống Không Cần Mở Hào Việc thực hiện chính xác trong quá trình lắp đặt không cần mở hào giúp đường ống duy trì độ bền và không va chạm với các tiện ích ngầm khác. Hãy xem xét các hệ thống hiện đại...

Xem Thêm

Phát Triển Cơ Sở Hạ Tầng Đô Thị với Các Máy Đẩy Ống Viễn Khả Thi Vai Trò của Công Nghệ Không Cần Mở Hào trong Phát Triển Đô Thị Hiện Đại Các kỹ thuật không cần mở hào như đẩy ống viễn khả thi hiện đã gần như trở thành yêu cầu bắt buộc khi cập nhật các tiện ích ngầm...

Xem Thêm

Thiết bị Bảo vệ Cá nhân (PPE) cho Vận hành Máy khoan Hầm: PPE Thiết yếu: Mũ bảo hiểm, Mặt nạ che mặt, Áo gi-lê phản quang và Bảo vệ hô hấp. Người vận hành máy khoan hầm cần được bảo vệ toàn thân vì họ liên tục đối mặt với nguy cơ...

Xem Thêm

Bảo trì Phòng ngừa để Tối đa Hóa Thời gian Hoạt động và Giảm Chi phí: Vai trò của Bảo trì Phòng ngừa trong Việc Giảm Thời gian Downtime của Thiết bị. Việc duy trì máy khoan hầm ở trạng thái tốt trước thời điểm xảy ra sự cố sẽ ngăn chặn các khoảng ngừng làm việc tốn kém, vì các vấn đề sẽ được khắc phục...

Xem Thêm

Điều Kiện Địa Chất: Độ Ổn Định Của Đất, Độ Cứng Của Đá và Tác Động Của Nước Ngầm. Đánh Giá Phân Tích Địa Chất và Địa Kỹ Thuật Của Địa Hình Để Lựa Chọn Máy Khoan Hầm Theo một nghiên cứu địa chất gần đây từ năm 2023, các đội thi công đã d...

Xem Thêm

Lắp Đặt Ít Gây Xáo Trộn Với Các Máy Khoan Micro Hầm. Các máy khoan micro hầm đã cách mạng hóa việc xây dựng ngầm bằng cách cho phép lắp đặt chính xác với mức độ xáo trộn bề mặt tối thiểu. Phương pháp này loại bỏ nhu cầu đào bới rộng rãi...

Xem Thêm