машината за добив на добив

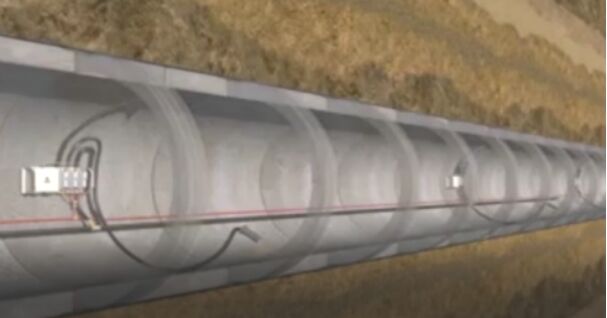

Машината за добив на мини е основно оборудване в областта на подземните разкопки, предназначена за прецизно и бързо пробиване на скали. Основните му функции включват пробиване на прави и извити дупки в минни тунели, което улеснява поставянето на експлозиви за взривяване или поставянето на поддържащи конструкции. Технологичните характеристики включват стабилна рамка, мотори с висок въртящ момент и автоматизирани системи за изкопчване, които позволяват непрекъсната работа с минимални прекъсвания. Тази машина също така включва усъвършенствана хидравлична система и компютърна система за управление, която гарантира точност и ефективност. По отношение на приложенията, машината за добив на мини се използва основно при добив на въглища, метали и други минерали, както и в проекти за гражданско строителство, които изискват прокопаване на тунели през твърда скала.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY