The Revolutionary Impact of Modern Tunneling Technology

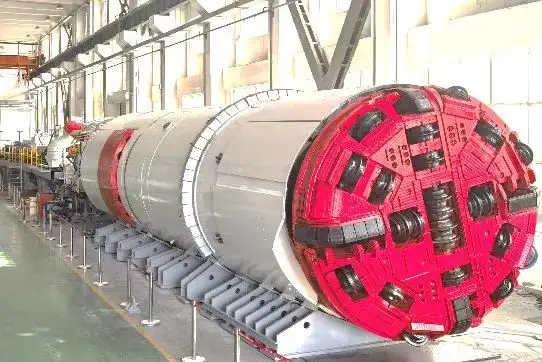

Tunnel boring machines (TBMs) have transformed the way we approach underground construction, offering unprecedented levels of safety and efficiency in tunneling operations. These massive mechanical marvels, often called 'underground factories,' have revolutionized infrastructure development across the globe. By combining cutting-edge engineering with robust safety systems, tunnel boring machines have become the gold standard for modern tunneling projects.

From subway systems to water transport networks, these sophisticated machines work tirelessly beneath our feet, creating vital infrastructure while maintaining the highest safety standards. Their ability to excavate through various ground conditions while simultaneously installing tunnel support systems has made them indispensable in modern construction.

Advanced Safety Features of Tunnel Boring Machines

Comprehensive Ground Control Systems

Modern tunnel boring machines incorporate sophisticated ground monitoring systems that continuously assess soil conditions and potential risks. These systems use advanced sensors and real-time data analysis to detect changes in ground pressure, water content, and soil composition. This constant monitoring allows operators to adjust machine parameters instantly, preventing ground subsidence and ensuring structural stability.

The machines also feature automatic ground support installation systems, which place reinforcement elements immediately after excavation. This immediate support significantly reduces the risk of cave-ins and provides a safer working environment for the crew.

Worker Protection Mechanisms

The safety of personnel is paramount in tunneling operations, and tunnel boring machines incorporate multiple layers of protection. Pressurized working chambers protect workers from groundwater intrusion and harmful gases. Advanced ventilation systems ensure a constant supply of fresh air and regulate temperature and humidity levels.

Emergency refuge chambers are built into the machines, providing safe havens with independent air supplies and communication systems in case of unexpected incidents. These chambers can sustain workers for extended periods until help arrives.

Speed Enhancement Technologies

Cutting-Edge Excavation Systems

Modern tunnel boring machines employ state-of-the-art cutting technologies that significantly increase excavation rates. High-performance cutting heads equipped with specialized disc cutters can efficiently break through various rock types. The machines' ability to adjust cutting pressure and rotation speed optimizes performance across different geological conditions.

Advanced debris removal systems work in tandem with the cutting mechanism, ensuring continuous operation without delays. Conveyor systems rapidly transport excavated material to the surface, maintaining optimal boring efficiency.

Automated Navigation and Control

Precision guidance systems enable tunnel boring machines to maintain accurate alignment throughout the excavation process. Using laser guidance and gyroscopic navigation, these machines can achieve remarkable precision, reducing the need for corrections and ensuring faster project completion.

Computer-controlled operation systems allow for real-time adjustments to boring parameters, optimizing performance while maintaining safety standards. This automation reduces human error and increases overall operational efficiency.

Efficiency Through Integration

Simultaneous Tunnel Lining Installation

One of the most significant advantages of tunnel boring machines is their ability to install tunnel lining segments while excavating. This concurrent operation dramatically reduces construction time compared to traditional methods. The machines precisely place and secure precast concrete segments, creating a strong and watertight tunnel structure.

The integration of lining installation with the boring process ensures immediate ground support, enhancing both safety and construction speed. This system allows for continuous operation, significantly reducing project timelines.

Logistics and Material Management

Modern tunnel boring machines feature sophisticated materials management systems that ensure a constant supply of necessary components. Automated systems handle the delivery of tunnel segments, grout, and other materials to the working face, minimizing downtime and maintaining consistent production rates.

Advanced logistics planning software coordinates material delivery with excavation progress, optimizing resource utilization and preventing delays. This integrated approach to materials management contributes significantly to project efficiency.

Future Innovations in Tunneling Technology

Artificial Intelligence Integration

The future of tunnel boring machines lies in the integration of artificial intelligence and machine learning capabilities. These technologies will enable machines to predict and adapt to changing ground conditions automatically, further improving safety and efficiency. AI-driven systems will optimize cutting parameters and maintenance schedules, reducing downtime and increasing productivity.

Development of autonomous operation capabilities will allow tunnel boring machines to work with minimal human intervention in hazardous conditions, enhancing safety while maintaining high performance standards.

Sustainable Tunneling Solutions

Next-generation tunnel boring machines are being designed with sustainability in mind. Electric power systems and energy recovery mechanisms will reduce environmental impact while maintaining high performance levels. Advanced filtration and water management systems will minimize the impact on groundwater resources.

These eco-friendly innovations will enable tunnel boring machines to meet increasing environmental regulations while delivering efficient and safe tunneling solutions for future infrastructure projects.

Frequently Asked Questions

What makes tunnel boring machines safer than conventional tunneling methods?

Tunnel boring machines provide continuous ground support, automated monitoring systems, and pressurized working environments. These features, combined with built-in emergency systems and real-time ground condition analysis, significantly reduce risks compared to conventional tunneling methods.

How do tunnel boring machines maintain consistent speed in varying ground conditions?

These machines utilize advanced sensors and control systems to automatically adjust cutting parameters based on ground conditions. Their integrated design allows for simultaneous excavation and tunnel lining installation, while sophisticated materials management systems ensure continuous operation.

What maintenance procedures ensure optimal performance of tunnel boring machines?

Regular maintenance includes inspection and replacement of cutting tools, checking hydraulic systems, and calibrating monitoring equipment. Predictive maintenance systems using sensor data help identify potential issues before they cause downtime, ensuring consistent performance and safety.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY