Essential Daily Maintenance Checks for Tunnel Drilling Machines

Daily maintenance of tunnel drilling machines is crucial to ensure their optimal performance and safe operation. Implementing a routine of pre-operation inspections can help identify potential issues before they escalate into serious problems. Here's a step-by-step guide to pre-operation inspection procedures:

Pre-Operation Inspection Procedures

- Conduct a Thorough Visual Inspection: Begin by visually inspecting the entire machine for any visible signs of wear or damage such as cracks, rust, or loose parts. This helps in identifying problems that could affect machine performance or safety.

- Check Fluid Levels: Assess vital fluid levels, including oil, coolant, and hydraulic fluids. Ensure they are within the recommended range to prevent overheating, mechanical failure, or reduced efficiency during operation.

- Evaluate Safety Features: Verify that safety systems such as emergency shut-off mechanisms and protective guards are intact and fully functional. This ensures the machine can be stopped in case of an emergency, enhancing operator safety.

Monitoring Hydraulic Systems and Pressure Gauges

Monitoring and maintaining hydraulic systems is vital for ensuring the machine's operational efficacy. Here are key areas to focus on:

- Hydraulic Fluid Levels and Clean Filters: Regularly check hydraulic fluid levels and replace or clean filters as needed to avoid performance dips and contamination.

- Pressure Gauge Monitoring: Keep an eye on pressure gauges for any unusual fluctuations which could be indicative of potential leaks or system failures. Prompt addressing of these issues can prevent costly breakdowns.

- Routine Sensor Calibration: Implement a schedule for calibrating hydraulic sensors to ensure they provide accurate readings. Incorrect sensor data can lead to operational mishaps and decrease efficiency.

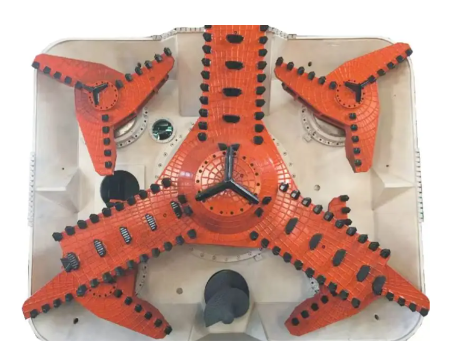

Clearing Debris from Cutting Heads

Maintaining the cutting heads is essential for the machine's effectiveness and longevity. Here’s how to manage debris removal:

- Ensure Debris-Free Cutting Heads: Check the cutting heads for debris buildup as trapped materials can hinder performance. Regular cleaning prevents excessive wear and maintains the effectiveness of the cutting tools.

- Systematic Cleaning Routine: Establish a routine that involves purging foreign materials from the cutting tool area. This systematic approach can help keep the machines running smoothly without hiccups.

- Use of Appropriate Tools and Gear: Utilize proper tools and safety gear to clear debris effectively while avoiding damage to sensitive components. This ensures that cleaning is done efficiently and safely.

These maintenance practices are fundamental to maintaining tunnel drilling machines in top working condition, reducing downtime, and extending the lifespan of the equipment. Regular checks and systematic procedures contribute significantly to operational success and safety standards.

Lubrication Strategies for Optimal Machine Performance

Selecting the Right Grease for Extreme Conditions

Choosing the appropriate grease for tunnel drilling machines operating under extreme conditions is crucial for ensuring optimal performance. First, it's imperative to analyze the operational environment, considering factors such as temperature, pressure, and exposure to chemicals that can affect grease choice. Multi-purpose greases designed to withstand extreme pressure and temperature fluctuations are recommended. Additionally, consulting manufacturer specifications provides compatibility with the machine components, ensuring the grease is suitable for its application. Employing the right grease not only enhances lubrication strategies but also extends the lifespan of critical components in demanding conditions.

Automated Lubrication System Maintenance

Maintaining the automated lubrication system of a tunnel drilling machine is essential to prevent operational disruptions. Regular inspection and maintenance help avoid breakdowns, ensuring continuous operations. A thorough check ensures lubrication lines are clear, free of obstructions, and properly distributing grease throughout the system. Furthermore, setting up a schedule for testing and replacing lubricants can promote system longevity and operational efficiency. Consistent maintenance of the lubrication system reduces the likelihood of unexpected failures and contributes significantly to the overall maintenance practices of the machine.

Detecting and Addressing Fluid Contamination

Regular detection and mitigation of fluid contamination in tunnel drilling machines safeguard system integrity and performance. Implementing routine sampling and analysis of machine fluids is critical, as it helps identify potential contaminants before they cause extensive damage. Using effective filtration systems can significantly mitigate the risk of fluid contamination. It's equally important to educate staff on recognizing signs of contamination, such as unusual colors or odors in fluids, to prompt timely interventions. Addressing fluid contamination proactively not only protects the machine but also ensures continued operational efficiency.

Wear Part Management and Replacement Cycles

Identifying Worn Drill Bits and Cutter Teeth

Identifying worn drill bits and cutter teeth is essential for effective wear part management. Implementing visual inspection protocols to regularly assess the condition of these critical components is vital. By looking for signs like chipped, uneven surfaces or unusual wear patterns, effective gauging of when parts need replacement can be done. Additionally, performance metrics such as drilling efficiency and the time taken for cuts provide valuable insights into the condition of the tools. Training operators to recognize declines in performance helps in timely identification of wear, ensuring that replacements happen before any serious damage occurs.

Proper Storage of Spare Components

Proper storage of spare components is vital for maintaining their integrity. Creating environments that prevent corrosion and physical damage to parts, often leveraging climate-controlled solutions, is crucial. Spare components are meticulously labeled and categorized, facilitating easy access and improved inventory management. An efficient inventory tracking system is crucial as it guarantees timely replacement of worn components, thus minimizing downtime. These practices ensure that spare parts remain in optimal condition and are readily available when needed.

Extending Service Life Through Rotation Practices

Extending service life through rotation practices is an effective wear management strategy. By adopting a rotation schedule for drill bits and cutting tools, a balance in wear across parts is achieved, preventing premature failure of any single component. Monitoring utilization statistics helps determine optimal rotation intervals, which are based on performance and wear rates. Providing comprehensive guidance on tool rotation ensures that the team maintains drilling integrity and efficiency, ultimately enhancing the service life of essential equipment.

Preventative Maintenance Scheduling

Creating Condition-Based Service Intervals

Establishing condition-based service intervals is crucial for optimizing machine performance and minimizing downtime. Evaluating machine performance data enables us to create servicing schedules that accurately reflect the actual working conditions rather than relying on arbitrary timelines. By incorporating technologies like IoT sensors, we can achieve real-time monitoring and detailed condition assessments. This forward-thinking approach not only reduces unexpected breakdowns but also boosts operational efficiency by aligning maintenance efforts with actual machine needs.

Vibration Analysis for Early Fault Detection

Vibration analysis is an invaluable tool for early fault detection in tunnel drilling machines. By monitoring machine health through vibration patterns, anomalies that indicate potential component failures before they escalate can be identified. Routine assessments of these patterns should be an integral part of the maintenance strategy to ensure ongoing reliability. This proactive maintenance practice helps in predicting issues, thus preventing costly breakdowns and enhancing the longevity of the equipment.

Maintaining Maintenance Logs for Audit Compliance

Establishing a robust logging system is essential for documenting all maintenance activities and inspections. Not only does this support audit compliance, but it also ensures adherence to industry regulations. Clear and comprehensive maintenance logs must be accessible for routine audits and compliance checks. Training staff on the importance of accurate record-keeping is paramount for promoting accountability and effective resource allocation, ultimately contributing to streamlined operations and regulatory compliance.

Troubleshooting Common Operational Issues

Addressing Overheating in Drivetrains

Overheating in drivetrain components is a prevalent issue that can compromise machine performance if not promptly addressed. To mitigate this, it's crucial to regularly monitor temperature readings from these components, allowing for early detection of overheating signs. This proactive measure ensures that any anomalies are quickly identified before leading to more significant damage. Evaluating coolant systems and heat exchangers plays a vital role in ensuring they function efficiently; any inefficiency can contribute to overheating. Suppose overheating trends are observed in the drivetrain. In that case, implementing specific cooling strategies or making operational adjustments can alleviate the problem, consequently enhancing the longevity and reliability of the equipment.

Resolving Alignment Deviations in Boring Paths

Precision in boring path alignment directly influences the efficiency and success of tunneling operations. Maintaining alignment accuracy is essential to avoid costly errors and ensure optimal performance. Regular alignment checks must be conducted to verify that the boring paths align with the machine specifications and project requirements. Using precision measuring tools to detect any misalignments can help identify their potential causes, assisting in the swift resolution of these issues. When deviations are identified, developing a corrective action plan is critical to maintaining operational precision and avoiding disruptions in tunneling activities.

Mitigating Dust Infiltration in Sensitive Components

Dust infiltration is a significant threat to the functionality of sensitive tunnel drilling machinery components. To prevent dust-related damage, it is vital to install dust covers and employ air filtration systems to shield these components. Regular inspections and cleaning of internal areas are necessary to prevent dust buildup over time, maintaining the machine's optimal performance levels. Moreover, educating operators on best practices to minimize dust exposure during operations can further safeguard the machinery. By implementing these preventative measures, we can ensure the seamless and efficient operation of tunnel drilling machines, thus maintaining productivity and reducing repair costs.

Frequently Asked Questions

Why are daily maintenance checks important for tunnel drilling machines?

Daily maintenance checks are crucial to identify potential issues early, ensuring optimal performance and safety, reducing downtime, and extending equipment lifespan.

How do I select the right grease for extreme conditions?

Selecting the right grease involves analyzing operational environment factors like temperature and pressure. Multi-purpose greases with extreme pressure and temperature resistance are recommended.

What is the importance of automated lubrication system maintenance?

Regular maintenance of the automated lubrication system prevents disruptions and ensures continuous operations by keeping lubrication lines clear and properly distributing grease.

How can I detect fluid contamination in tunnel drilling machines?

Fluid contamination can be detected through routine sampling and analysis of machine fluids, which help identify potential contaminants before causing damage.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY