Revolutionizing Underground Construction With Advanced Technology

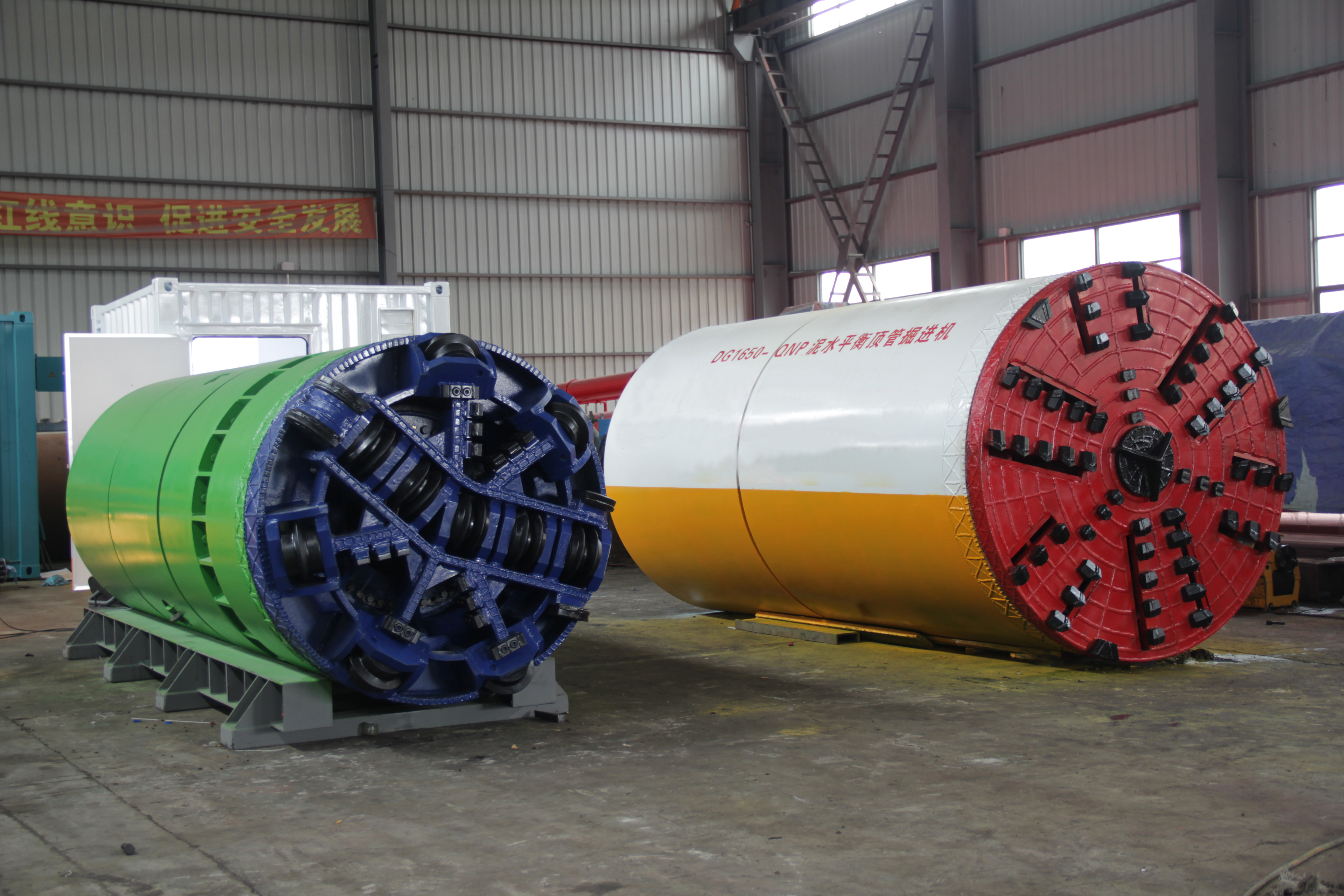

Modern trenchless construction methods have transformed underground utility installation, with pipe jacking machines leading this quiet revolution in urban infrastructure development. These sophisticated systems enable precise pipe installation beneath sensitive surfaces without disruptive excavation, minimizing impact on urban landscapes and daily life. Pipe jacking machines combine hydraulic power with precision guidance systems to install pipelines of various diameters while maintaining surface integrity above. The technology has become indispensable for projects requiring minimal surface disturbance, such as under roadways, railways, or historic districts. Municipalities and contractors increasingly favor pipe jacking machines for their ability to complete projects faster than traditional open-cut methods while reducing overall project costs. This innovative approach to underground construction addresses many challenges that have plagued conventional excavation techniques for decades.

Minimal Surface Disruption Benefits

Preserving Urban Infrastructure Integrity

Pipe jacking machines excel in urban environments where maintaining surface structures is paramount. The technology allows tunneling beneath roads without compromising pavement integrity or requiring costly reconstruction. Sensitive areas like airport runways, railway tracks, and historic districts benefit tremendously from pipe jacking machine applications that prevent surface settlement. The process eliminates the need for extensive trench shoring and backfill compaction that open-cut methods require. Municipalities appreciate how pipe jacking machines can install utilities beneath existing infrastructure without disrupting traffic patterns or business operations. This advantage proves particularly valuable in densely populated areas where even short-term road closures create significant economic impacts.

Reduced Community Impact and Noise Pollution

The trenchless nature of pipe jacking machine operations dramatically decreases noise levels compared to conventional excavation. Vibrations from the equipment remain contained underground rather than transmitting through surface structures. This quiet operation allows construction to proceed during nighttime hours in noise-sensitive areas like hospital districts or residential neighborhoods. Pipe jacking machines generate minimal dust and airborne particulates that typically plague open trench projects. The reduced surface footprint means fewer construction vehicles moving through communities, decreasing traffic congestion and associated emissions. These community-friendly characteristics make pipe jacking machine projects more likely to receive quick approval from local planning boards and residents.

Enhanced Project Efficiency Metrics

Accelerated Project Timelines

Pipe jacking machines can complete pipeline installations up to 40% faster than traditional open-cut methods in urban conditions. The continuous operation of pipe jacking machines eliminates time-consuming steps like trench shoring, dewatering, and backfilling. Projects avoid weather-related delays that frequently impact open excavations during rainy seasons. The ability to work beneath surface obstacles without relocation or support means fewer project interruptions. Pipe jacking machines maintain consistent progress rates regardless of surface conditions overhead, whether paved roads, landscaped areas, or water bodies. Municipalities benefit from shorter project durations that reduce overall community impact and restore normal operations quicker.

Cost-Effectiveness in Urban Settings

While pipe jacking machine technology requires significant initial investment, the total project savings often prove substantial. The method eliminates costs associated with trench shoring, surface restoration, and traffic control measures. Pipe jacking machines reduce expenses related to utility relocation and surface structure protection common in open-cut projects. The technology minimizes indirect costs like business interruption claims and detour maintenance. Pipe jacking machine projects typically require smaller crews than conventional excavations, lowering labor costs. When factoring in all direct and indirect expenses, municipalities often find pipe jacking machine methods deliver 20-30% cost savings for urban pipeline projects compared to traditional approaches.

Precision Installation Capabilities

Accurate Grade and Alignment Control

Modern pipe jacking machines incorporate advanced laser guidance systems that maintain precise grade and alignment throughout installation. The technology can achieve accuracy within millimeters over hundreds of meters of pipeline. This precision proves critical when connecting to existing infrastructure or maintaining specific gravity flow requirements. Pipe jacking machines compensate for varying ground conditions that might deflect conventional tunneling methods. The controlled installation process minimizes the risk of misalignment that could require costly corrective work. Engineers appreciate how pipe jacking machines can navigate complex underground pathways while maintaining design specifications exactly.

Adaptability to Challenging Geologies

Pipe jacking machines perform well in diverse soil conditions ranging from soft clays to dense sands and gravels. The equipment can be fitted with specialized cutting heads to handle rock formations or mixed-face conditions. Pipe jacking machines maintain stability in water-bearing soils better than open excavations, reducing dewatering requirements. The technology allows installation through contaminated soils without bringing them to the surface, addressing environmental concerns. Contractors can adjust jacking forces and advance rates in real-time based on ground conditions encountered during operation. This adaptability makes pipe jacking machines suitable for projects where soil conditions vary significantly along the pipeline route.

Safety and Risk Mitigation

Enhanced Worker Safety Conditions

Pipe jacking machine operations significantly reduce construction-related injuries compared to open trench methods. Workers avoid hazards associated with deep excavations like cave-ins, falls, and equipment strikes. The enclosed nature of pipe jacking machine operations protects crews from weather extremes and reduces exposure to airborne contaminants. The technology eliminates risks associated with traffic control in busy urban work zones. Pipe jacking machine projects require fewer heavy equipment movements at ground level, decreasing accident potential. These safety advantages translate to lower insurance costs and reduced liability for contractors and municipalities.

Reduced Utility Strike Risks

The controlled environment of pipe jacking machine operations dramatically decreases the chance of accidental utility strikes. Precise guidance systems allow tunneling between existing underground infrastructure with minimal clearance requirements. Pipe jacking machines can install new utilities beneath sensitive existing pipelines without disturbing them. The technology eliminates the guesswork of traditional excavation where undocumented utilities frequently cause dangerous encounters. Municipalities benefit from reduced service interruptions and emergency repair costs associated with utility damage. This precision proves especially valuable in congested urban utility corridors where multiple infrastructure systems coexist in limited underground space.

Environmental Sustainability Advantages

Minimal Ecological Disturbance

Pipe jacking machine technology preserves surface ecosystems by eliminating the need for extensive excavation. The method protects tree root systems that would be damaged by traditional trenching in landscaped areas. Pipe jacking machines can install pipelines beneath water bodies without disturbing aquatic habitats or water quality. The technology reduces sediment runoff that typically requires containment measures in conventional projects. Pipe jacking machine operations generate significantly less construction waste destined for landfills compared to open-cut methods. These environmental benefits help projects earn green construction certifications and satisfy stringent environmental regulations.

Reduced Carbon Footprint

The trenchless nature of pipe jacking machine projects results in substantially lower greenhouse gas emissions. Fewer construction vehicles on site decrease diesel exhaust emissions common in traditional excavations. Pipe jacking machines require less energy-intensive backfill materials and compaction equipment. The shorter project durations reduce overall fuel consumption and associated emissions. Pipe jacking machine methods preserve existing carbon-sequestering landscapes that would be disturbed by open trenching. Municipalities pursuing climate action plans increasingly favor pipe jacking machine technology for its alignment with sustainability goals.

FAQ

What diameter range can pipe jacking machines handle?

Modern pipe jacking machines accommodate diameters from 750mm to 3000mm, with specialized systems available for both smaller and larger pipeline requirements.

How does pipe jacking compare to horizontal directional drilling?

Pipe jacking machines provide more precise grade control and can handle larger diameters than HDD, while being better suited for shorter runs in urban environments.

What types of pipe materials work with jacking systems?

Pipe jacking machines commonly work with concrete, clay, steel, and fiberglass-reinforced pipes designed to withstand jacking forces during installation.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY