quality microtunneling machine price

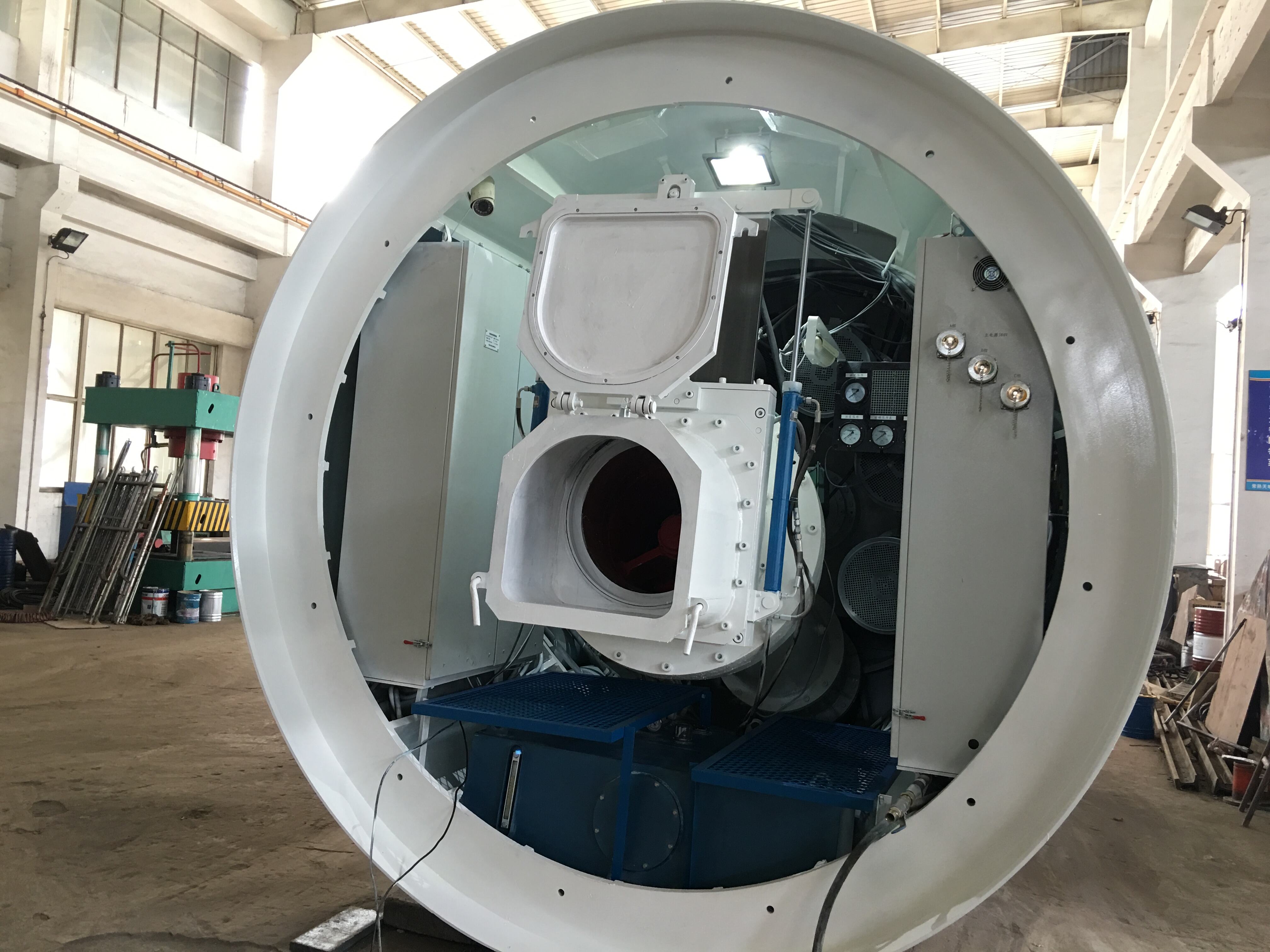

The price of a quality microtunneling machine encompasses not just the initial outlay but the value it brings through its sophisticated functions and advanced technology. Designed for underground utility installations, these machines are equipped with precision steering systems that enable accurate tunnel alignment. Their main functions include drilling through soil and rock, installing pipes or conduits, and ensuring the stability of the tunnel during the process. Technological features such as laser guided systems, remote control capabilities, and automatic thrust systems contribute to their efficiency. These machines find their primary applications in urban environments for the installation of water, gas, and sewage lines, as well as in subway and road construction projects. The price reflects the robustness and reliability of the machine, essential for the challenging environments in which they operate.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY