The Revolutionary Impact of Modern Underground Construction Methods

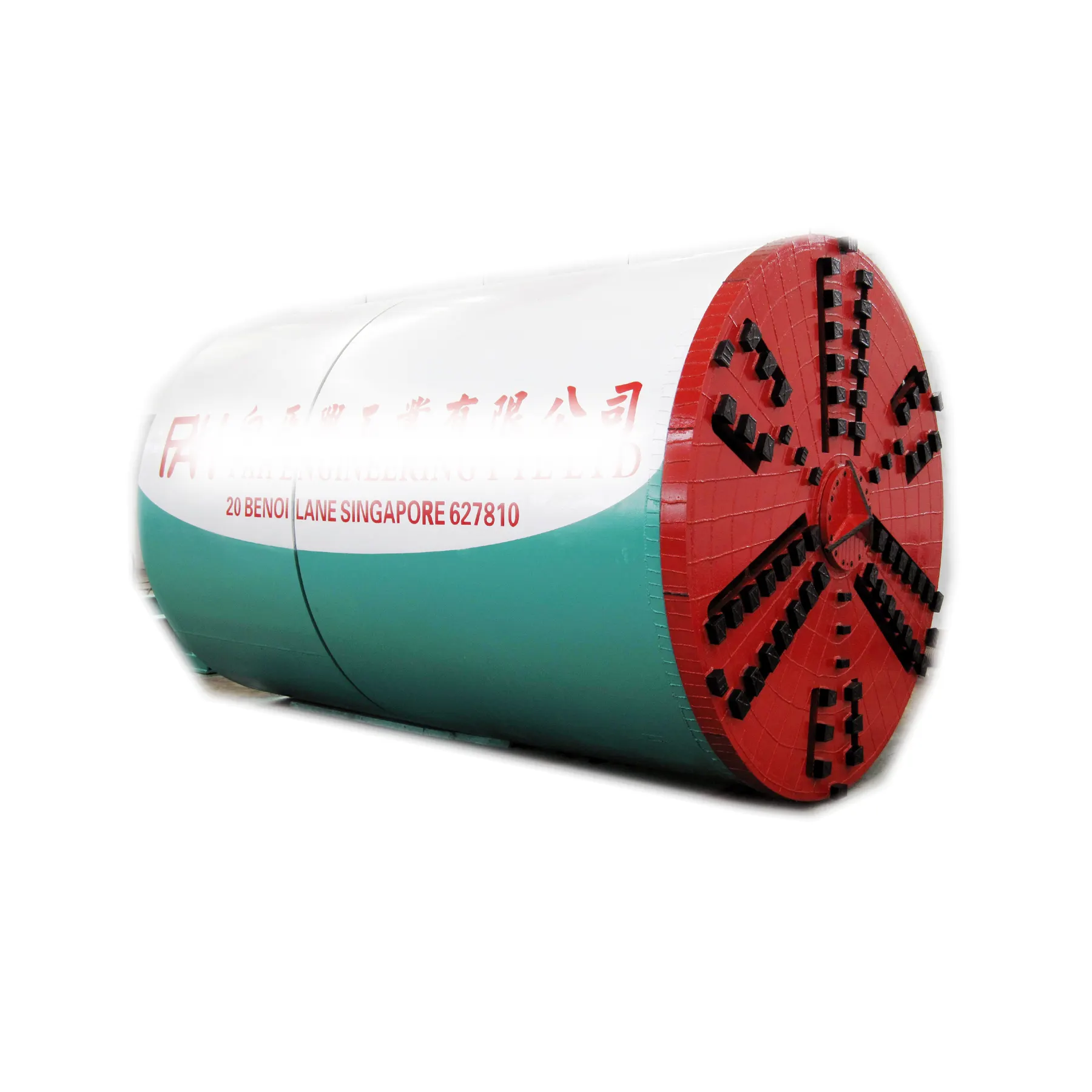

The construction industry has witnessed a paradigm shift with the advent of trenchless technology, transforming how we approach underground infrastructure projects. This innovative methodology has become increasingly prevalent in urban development, utility installation, and pipeline rehabilitation projects worldwide. By minimizing surface disruption and streamlining construction processes, trenchless technology offers remarkable advantages in terms of both labor efficiency and cost reduction.

Traditional excavation methods often require extensive manpower, heavy machinery, and significant time investments, leading to substantial project costs and community disruption. In contrast, trenchless technology provides a sophisticated alternative that addresses these challenges while delivering superior results. As municipalities and contractors face mounting pressure to complete projects efficiently and economically, understanding the labor and cost benefits of trenchless solutions becomes increasingly vital.

Economic Advantages of Trenchless Construction Methods

Direct Cost Savings Through Reduced Labor Requirements

One of the most significant advantages of trenchless technology lies in its ability to dramatically reduce labor costs. Traditional open-cut methods typically require large crews working for extended periods, whereas trenchless projects can often be completed with smaller teams. This reduction in manpower requirements can lead to labor cost savings of up to 30-50% compared to conventional methods.

The efficiency of trenchless operations means that projects can be completed in a fraction of the time needed for traditional excavation. With specialized equipment and skilled operators, crews can install or rehabilitate underground infrastructure more rapidly, resulting in reduced labor hours and associated costs. This increased productivity translates directly to improved project economics and better resource allocation.

Minimized Surface Restoration Expenses

Surface restoration represents a substantial portion of traditional excavation project budgets. Trenchless technology significantly reduces or eliminates the need for extensive surface repairs, as it requires minimal ground disruption. This translates to considerable savings in materials, labor, and time typically required for restoring pavements, landscaping, and other surface features.

The reduction in restoration requirements not only decreases direct project costs but also minimizes long-term maintenance expenses. Properties and infrastructure affected by the construction remain largely intact, eliminating the need for ongoing repairs and maintenance that often plague traditionally excavated areas.

Operational Efficiency and Project Timeline Benefits

Accelerated Project Completion Rates

Trenchless technology enables significantly faster project completion compared to conventional methods. Projects that might take weeks or months using traditional excavation can often be completed in days using trenchless techniques. This acceleration of timeline delivers multiple benefits, including reduced labor hours, lower equipment rental costs, and minimized project overhead expenses.

The speed advantage of trenchless methods becomes particularly valuable in urban environments where time constraints and access limitations pose significant challenges. The ability to complete projects quickly while maintaining access to businesses and residences represents a major operational advantage that contributes to overall cost reduction.

Reduced Equipment and Resource Requirements

While trenchless technology requires specialized equipment, the overall resource requirements are often lower than traditional methods. Fewer pieces of heavy machinery are needed on-site, resulting in reduced equipment rental and operational costs. The focused nature of trenchless operations also means less material waste and more efficient use of construction resources.

The streamlined equipment needs translate to lower fuel consumption, reduced maintenance costs, and decreased logistics expenses. These operational efficiencies contribute significantly to the overall cost-effectiveness of trenchless projects, particularly on larger-scale installations or rehabilitation efforts.

Environmental and Social Cost Benefits

Minimized Environmental Impact

Trenchless technology significantly reduces the environmental footprint of underground construction projects. The minimal surface disruption results in decreased soil disturbance, reduced erosion risks, and lower carbon emissions from heavy equipment operation. These environmental benefits often translate to cost savings through reduced environmental compliance requirements and mitigation measures.

The preservation of existing landscapes and vegetation eliminates the need for extensive environmental restoration work, further contributing to project cost savings. Additionally, the reduced equipment operation time results in lower fuel consumption and associated environmental impact costs.

Reduced Social and Business Disruption Costs

The economic impact of construction projects extends beyond direct costs to include social and business disruption expenses. Trenchless technology minimizes these indirect costs by maintaining access to businesses, reducing traffic disruption, and preserving normal community activities. This reduction in social impact can result in significant cost savings for project stakeholders and affected communities.

Businesses near construction sites often experience minimal disruption to their operations, preventing lost revenue and maintaining customer access. The reduced impact on traffic flow also minimizes economic losses associated with congestion and detours, contributing to the overall cost-effectiveness of trenchless solutions.

Future Cost Implications and Long-term Benefits

Extended Infrastructure Lifespan

Trenchless technology often results in installations and repairs that have longer service lives compared to traditional methods. The precision of installation and quality of materials used in trenchless applications can extend infrastructure lifespan by 50-100 years, reducing the frequency of required maintenance and replacement.

This increased durability and reliability of trenchless installations translates to significant long-term cost savings through reduced maintenance requirements and extended replacement intervals. The initial investment in trenchless technology often pays dividends through improved infrastructure performance and longevity.

Technological Advancements and Cost Reduction Trends

Ongoing developments in trenchless technology continue to drive down costs while improving efficiency and capabilities. New equipment innovations, improved materials, and refined techniques contribute to making trenchless methods increasingly cost-competitive. These technological advances often result in further labor reductions and operational efficiencies.

As the industry continues to evolve, the cost advantages of trenchless technology are expected to become even more pronounced. Improved automation, enhanced materials, and more efficient processes will likely lead to additional cost reductions and labor savings in future applications.

Frequently Asked Questions

What is the typical cost savings percentage when using trenchless technology?

Projects utilizing trenchless technology typically realize cost savings of 25-40% compared to traditional excavation methods, with some projects achieving even higher savings depending on specific conditions and requirements. These savings come from reduced labor needs, faster completion times, and minimal restoration requirements.

How does trenchless technology impact project timelines?

Trenchless projects can often be completed in 50-80% less time than conventional excavation methods, significantly reducing labor hours and associated costs. This accelerated timeline also minimizes disruption to surrounding areas and allows for quicker project completion.

What types of projects benefit most from trenchless technology?

Urban infrastructure projects, utility installations beneath roadways or waterways, and pipeline rehabilitation projects typically benefit most from trenchless technology. These applications see the greatest cost and labor savings due to reduced surface disruption and simplified construction processes.

What are the initial investment requirements for trenchless equipment?

While specialized trenchless equipment may require significant initial investment, the long-term cost savings and increased project efficiency typically provide a strong return on investment within 1-2 years for contractors regularly engaged in underground construction work.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY