Essential Factors in Trenchless Equipment Investment

The decision to invest in trenchless machinery represents a significant milestone for any construction or utility company. This advanced technology has revolutionized underground construction and rehabilitation work, offering efficient alternatives to traditional open-cut methods. Making an informed decision requires careful consideration of multiple factors that can impact both immediate operations and long-term success.

The trenchless machinery market continues to evolve with technological advancements, making it crucial for businesses to understand the complexities involved in selecting the right equipment. From initial capital requirements to operational capabilities, each aspect plays a vital role in determining the return on investment and overall project success.

Financial Considerations for Equipment Acquisition

Purchase Costs and Financing Options

The initial investment in trenchless machinery can be substantial, requiring careful financial planning. New equipment costs can range from several hundred thousand to millions of dollars, depending on the type and capabilities. Companies must evaluate their available capital, consider financing options, and assess potential tax benefits or incentives for equipment purchases.

Various financing alternatives exist, including traditional bank loans, equipment leasing, and manufacturer financing programs. Each option comes with its own advantages and considerations, such as interest rates, term lengths, and impact on cash flow. It's essential to analyze how different financing structures align with projected revenue streams and business growth plans.

Operating Costs and Return on Investment

Beyond the purchase price, understanding the total cost of ownership is crucial. This includes fuel consumption, maintenance requirements, operator training, and replacement parts. Regular maintenance costs can vary significantly between different manufacturers and models, impacting the long-term financial viability of the investment.

Calculate the potential return on investment by considering factors such as project pipeline, typical job sizes, and local market demands. Equipment utilization rates play a crucial role in determining profitability, making it essential to have a clear business plan and projected workload before making the investment.

Technical Specifications and Performance Requirements

Equipment Capabilities and Limitations

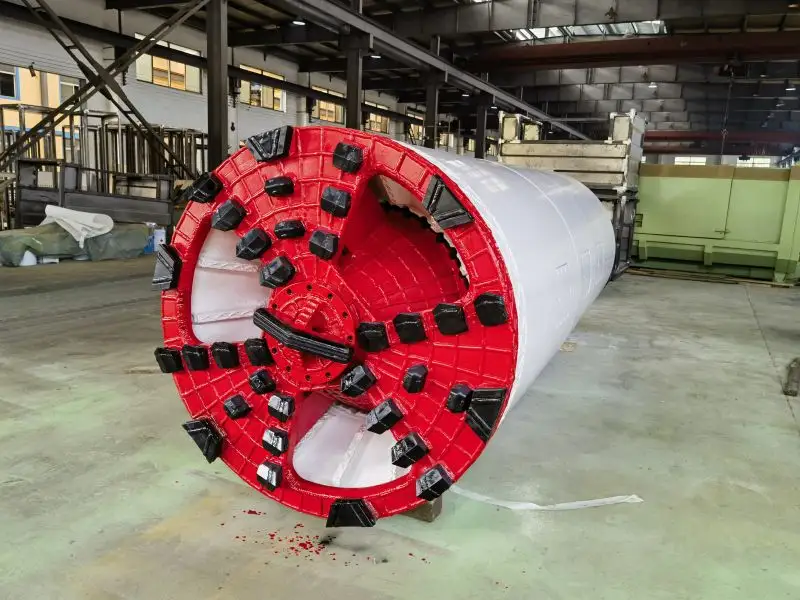

Different trenchless machinery types serve specific purposes, from horizontal directional drilling to pipe bursting systems. Understanding the technical specifications, including maximum boring distances, pulling forces, and soil compatibility, is crucial for matching equipment to project requirements.

Consider the typical ground conditions in your operating area, as some machines perform better in certain soil types than others. Evaluate features such as steering capabilities, thrust and pullback forces, and torque ratings to ensure the equipment can handle anticipated project demands.

Technology Integration and Control Systems

Modern trenchless machinery often incorporates advanced technology for improved accuracy and efficiency. Assess the control systems, GPS integration capabilities, and data logging features that can enhance project execution and documentation. The level of automation and user interface sophistication can significantly impact operator efficiency and project outcomes.

Consider the compatibility with existing equipment and software systems in your organization. Integration capabilities can streamline operations and improve overall productivity when multiple pieces of equipment work together seamlessly.

Operational Considerations and Support Infrastructure

Training and Workforce Development

Investing in trenchless machinery requires a skilled workforce capable of operating and maintaining the equipment effectively. Factor in the costs and time required for operator training, including both initial certification and ongoing skill development. Some manufacturers offer comprehensive training programs as part of the purchase package.

Consider the availability of qualified operators in your area and the potential need to develop internal training programs. The complexity of modern trenchless systems demands a commitment to continuous education and skill enhancement for optimal equipment utilization.

Maintenance and Support Services

Access to reliable maintenance support and spare parts is crucial for minimizing downtime and maintaining equipment performance. Evaluate the manufacturer's service network, response times, and parts availability in your operating region. Some providers offer remote diagnostics and preventive maintenance programs that can help avoid costly breakdowns.

Consider establishing relationships with local service providers and maintaining an inventory of critical spare parts. The availability of technical support and emergency repair services can significantly impact project timelines and customer satisfaction.

Market Analysis and Business Strategy

Industry Trends and Growth Opportunities

Understanding current market trends and future growth prospects in the trenchless sector helps inform equipment investment decisions. Analysis of local infrastructure development plans, utility upgrade projects, and environmental regulations can provide insights into potential business opportunities.

Consider factors such as urbanization patterns, aging infrastructure replacement needs, and environmental concerns that drive demand for trenchless solutions. This understanding helps in selecting equipment that aligns with both current needs and future market evolution.

Competitive Positioning and Specialization

Evaluate how new trenchless machinery can differentiate your services in the market. Consider specializing in specific types of projects or techniques where competition might be less intense. The right equipment investment can open new market segments and create competitive advantages.

Assess the local competitive landscape and identify underserved niches that align with your expertise and equipment capabilities. Building a reputation in specialized services can lead to premium pricing and stronger client relationships.

Frequently Asked Questions

How long does trenchless machinery typically last?

The lifespan of trenchless machinery varies depending on usage patterns, maintenance practices, and operating conditions. With proper maintenance and regular servicing, quality equipment can remain productive for 10-15 years or more. However, technological advances might make upgrading beneficial before the end of the physical lifespan.

What are the most important maintenance practices for trenchless equipment?

Key maintenance practices include daily inspections, regular fluid changes, wear part replacement, and adherence to manufacturer-recommended service intervals. Implementing a preventive maintenance program, keeping detailed service records, and training operators in basic maintenance procedures are essential for equipment longevity.

How can companies maximize their return on investment in trenchless machinery?

To maximize ROI, companies should focus on maintaining high utilization rates, efficient project planning, proper operator training, and preventive maintenance. Developing diverse revenue streams, building strong client relationships, and staying current with industry trends also contribute to better returns on equipment investments.

What financing options are typically available for trenchless equipment purchases?

Common financing options include traditional bank loans, equipment-specific financing, leasing arrangements, and manufacturer financing programs. Each option offers different benefits in terms of cash flow management, tax advantages, and flexibility. Working with financial advisors can help determine the most advantageous financing structure for your situation.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY