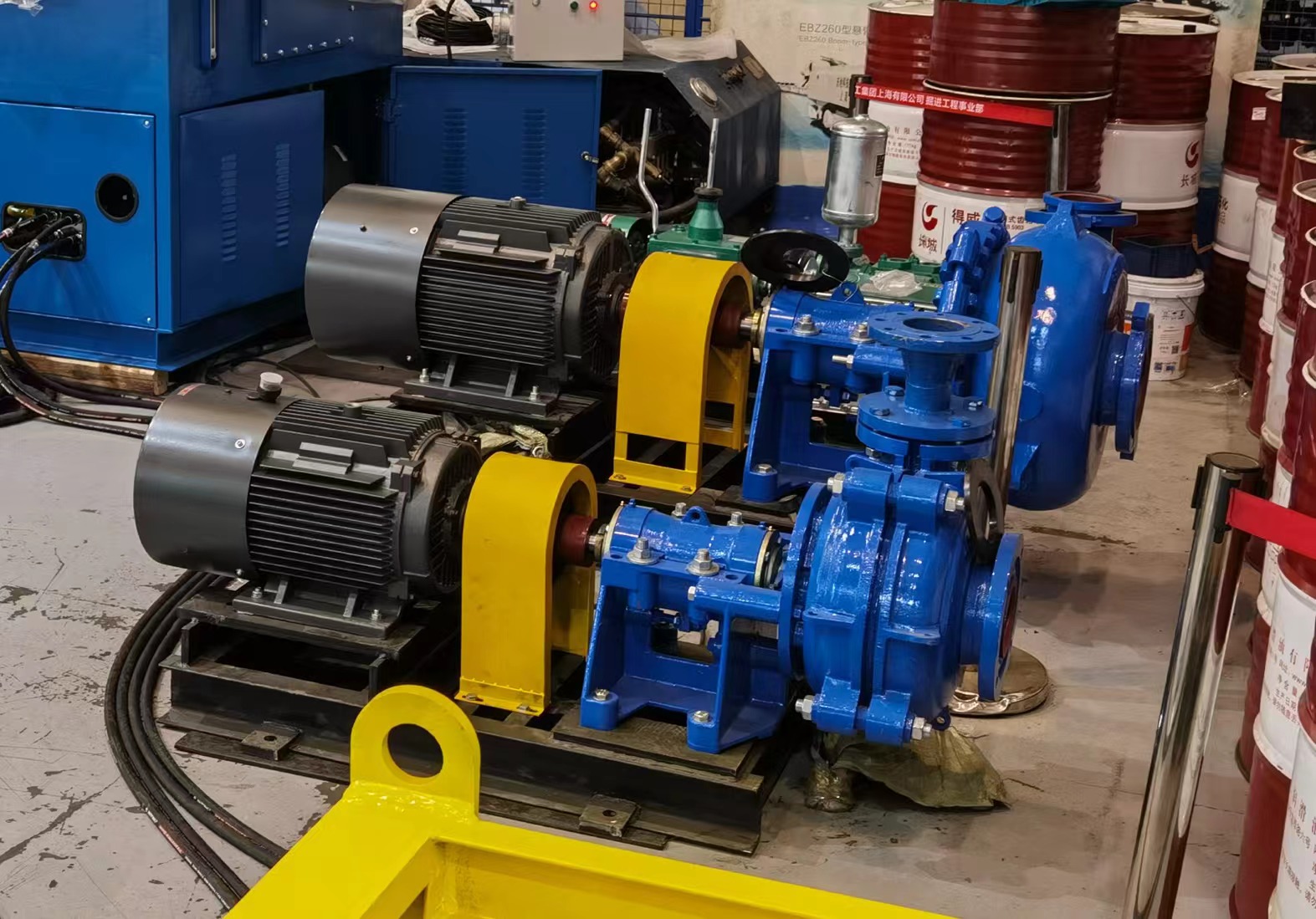

tunneling equipment

Tunneling equipment refers to the range of machinery and tools designed for the excavation and construction of tunnels. The primary functions of this equipment include drilling, boring, cutting, and removing soil and rock to create a passageway. Technological features vary depending on the specific type of machinery, but often include computerized control systems for precision, hydraulic systems for power, and advanced sensors for safety monitoring. The applications of tunneling equipment are diverse, spanning from underground transportation systems like subways and road tunnels to utility installations and mining operations. These machines are engineered to handle different ground conditions and are vital for the efficient and safe execution of underground projects.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY